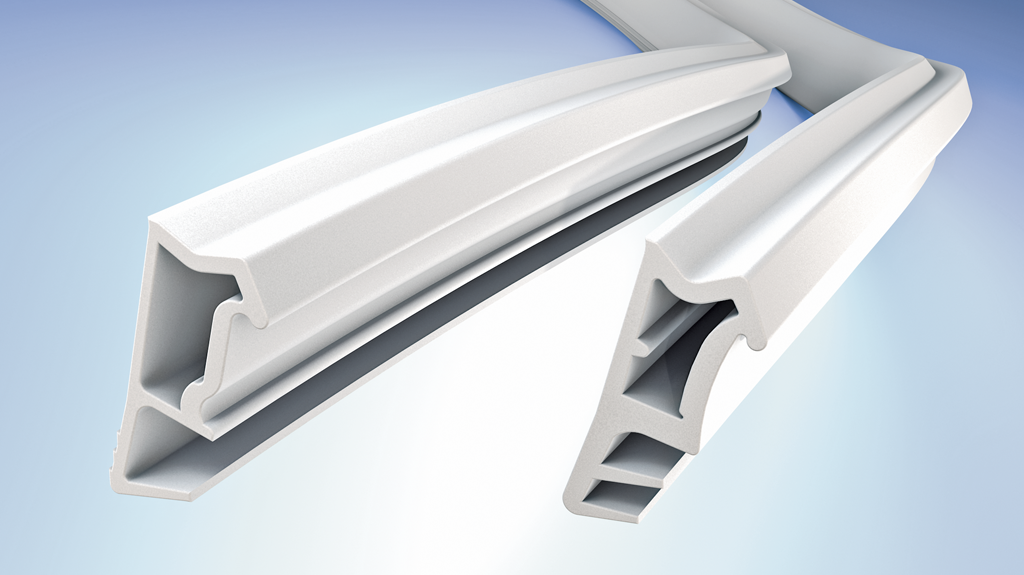

Extruded profile solutions

Solutions tailored for doors and windows that make you stay ahead of competition. Along the customized solutions we offer an assortment of standard profiles which makes your ordering process fast and flexible. A partial list of our capabilities includes sealing and glazing strips, combining solid mounts with a soft and flexible sealing part, enabling automatic insertion or machine mounting, unique air and water tightness, heat insulation and noise reduction.

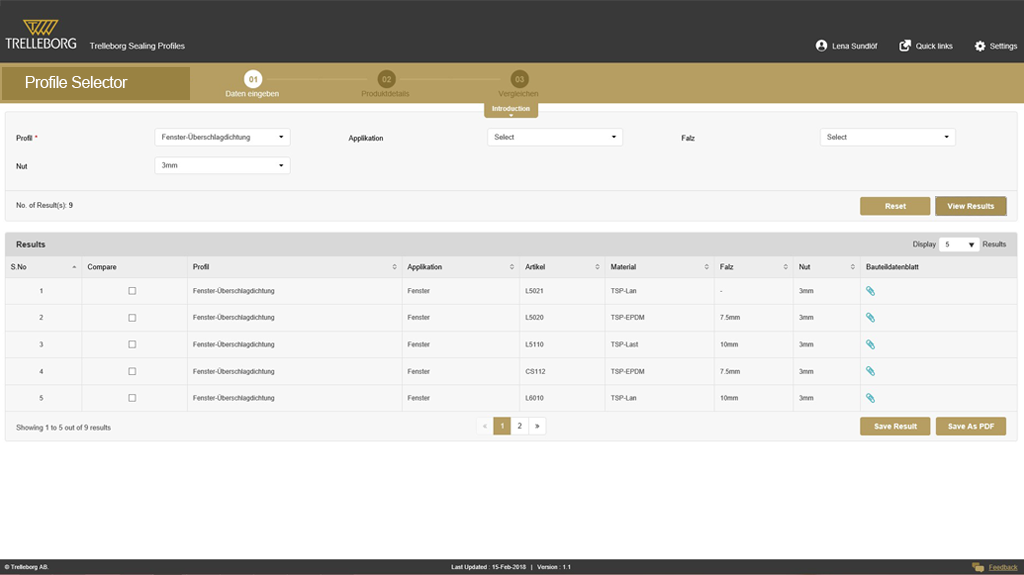

Benefits of choosing the right seal