More than just pipe dreams

An advanced system for making rubber seals significantly improves the efficiency of manufacturing huge concrete pipes, helping to make sure the sections will fit together without leaking.

Anyone seeing the massive concrete pipes used for sewers and culverts might assume that making them is a fairly simple matter of pouring concrete into a mould and waiting for it to harden.

But manufacturing concrete pipe is actually a very demanding process. It requires the right consistency of concrete and in most processes a lot of vibrating to make sure the concrete is compacted properly. Pipes are generally made in vertical moulds and can weigh upward of seven tons, depending on the diameter of pipe. Pipes made with integrated sealing systems include cast-in rubber seals to assure there’s no leakage when pipe sections are joined together on site.

However, the vibration needed to make a pipe correctly is bad news for those seals, which can be displaced in the manufacturing process. “The concept of integrating seals into manufactured pipe has been around for more than 35 years, but until recently, most seals have been a bit of a compromise. That has changed thanks to the new Trelleborg 165,” says Julian West, Product Manager for pipe seals within Trelleborg Industrial Solutions.

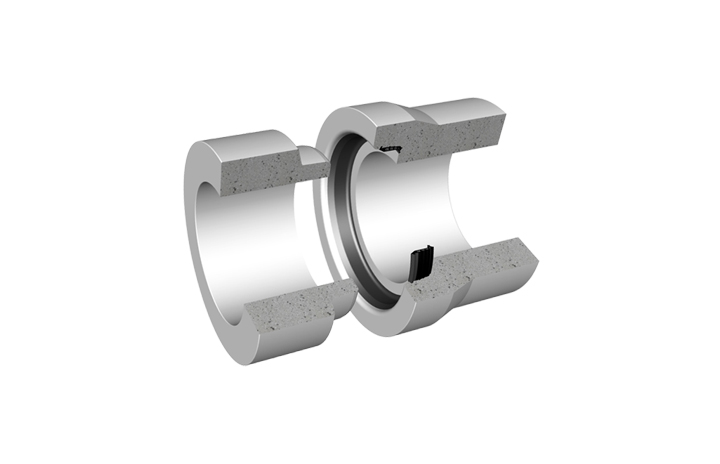

The Trelleborg 165 is a pipe sealing system that uses two grades of rubber to create an integrated seal which stays in place during manufacturing despite the vibrations. A harder rubber gives a superior tension against the steel pallet used in the pipe-making process, reducing any possibility of a seal moving out of place.

“It outperforms anything we’ve made before and everything else on the market currently,” West says. “The biggest advantage is the stability of this seal during the manufacture of the pipes.” Pipe makers can’t tell if a seal has moved until after a pipe has cured. And if one has been displaced, all they can do at that point is scrap the pipe. The Trelleborg 165 significantly cuts scrap rates, West says. “Our seal isn’t going to be part of the daily issues that the pipe manufacturer faces in his production,” he says.

Trelleborg began marketing the new seal for the most widely used pipe sizes in the UK in early 2015. Since then, it has been embraced by concrete pipe and manhole manufacturers in Germany, France and Belgium, Poland, Norway and Sweden. "German pipe associations recommended it", West says, “which seems only natural, given their high manufacturing standards.”

Besides making the manufacturing process easier, the Trelleborg 165 also simplifies the pipe installation process. The new seal requires fewer installers in a trench and is ideal for mechanized pipe laying, reducing health and safety issues on site. As the reference project below shows, we enable customers to save time, while being safe!

“This seal is proving to be extremely efficient in what it does,” West concludes. That’s good news for our customers, and for Trelleborg.