Turning challenges into new opportunities

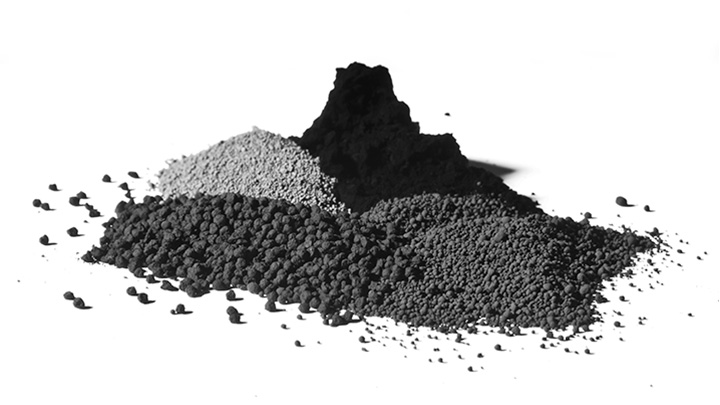

Materials can have completely different properties and are unique depending on each industry, this can play a key role in the success of your products and solutions.

Our team of professionals with wide expertise in material technology, will help you to make the right choice for your application.

Our portfolio contains most types of rubber polymers such as EPDM, NBR, SBR, NR, CR, HNBR, XNBR, ECO, AEM, IIR, and EVA

Key features & benefits

- High competence (over 100 years of experience)

- Wide range of materials

- Supply to all kinds of industries

- Customized products

- Well-equipped lab and a highly skilled R&D team

Latest News and Events!

Stay tuned!

Recorded webinars

Missed our last webinar?

Resources

Here you can download certificates, general terms & conditions of delivery and data sheets

Our location

Trelleborg Mixing Forsheda AB

C P.O.Box 1004 SE-331 29 Värnamo Visiting address: Storgatan 28, Forsheda , SwedenTel: +46 370 481 00

Fax: +46 370 817 73