Trelleborg Fluid Handling Solutions

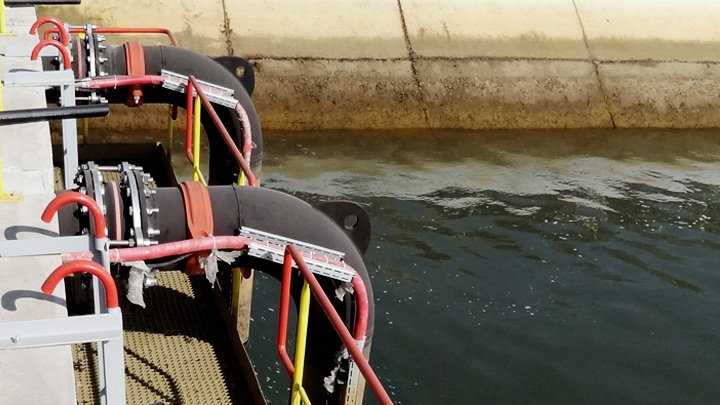

Our extensive portfolio includes industrial hoses and couplings, filtration, sheeting and matting, expansion joints and wear protection lining equipment. Explore our product ranges below, or visit the Your Industry page to explore solutions by application.

Expertise videos

We provide solutions for oil and gas transfer, marine applications, fluid handling systems for industrial applications and full material and equipment protection in the mining industry.

Hose assemblies solutions for Building & Construction

Trelleborg provides builders with the widest hose assemblies solutions: : deep foundations, concrete piles, compressed air shotcrete, tunnel concrete sprayer, concrete pumping, concrete skips, tunnel slurry.

Mining Products & Solutions

Trelleborg's engineered products operation is at the forefront of innovative systems and materials for use in all mining wear protection applications. We engineer rubber and composite ceramics to protect deflectors and chutes from high wear materials in screening systems and provide complete mill overhaul kits from lifter bars to pulp lifters.

Agricultural and Aquaculture Hoses

Hose and hose assembly solutions for spraying, irrigation, spreading, in open fields as well as in greenhouses.

Solutions & Services

Latest innovations, case stories, Q&A