Trelleborg Showcases Medical Device Innovations at MEDI’NOV Connection

Unique multicomponent parts

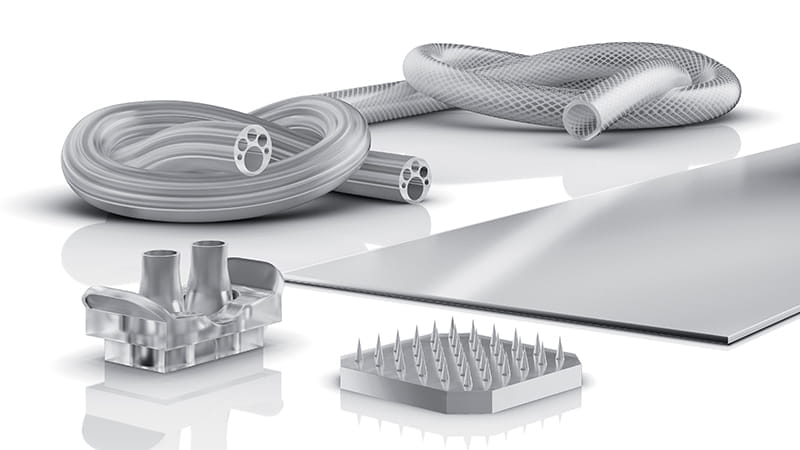

Visitors to the Trelleborg stand can learn about specialist multicomponent technology that creates unique components beyond the capability of other methods, extending the boundaries of manufacturing innovation. Medical equipment manufacturers benefit from a process that helps meet their design goals, including reducing the size and weight of components, while increasing their robustness and improving quality, lowering total cost of ownership.

Trelleborg’s Liquid Silicone Rubber (LSR) experts employ highly sophisticated tools and process engineering to develop novel solutions, combining two or more individual materials and parts into one fully bonded, robust component. This multicomponent injection molding or co-injection – commonly referred to as 2K or 2-shot – produces parts that are more hygienic, eradicating the dead space where bacteria can breed, and lowers costs by cutting out assembly and reducing the number of components in the customer’s supply chain.

>>Find out more about multicomponent technology

Miniaturized wearable and implantable devices

A related technology – micromolding - is critical to the miniaturization of devices so small they are wearable and implantable. Components below 10 milligrams in weight are possible using needlepoint injection technology and fully automated parts handling. Trelleborg’s high dimensional flashless and wasteless design principles create micromolded parts virtually flash-free and not requiring secondary deflashing.

>>Find out more about micromolding and overmolding

Emmanuel Louison, Sales Engineer at Trelleborg Sealing Solutions, says: “With the development of ever-smaller sophisticated medical devices, component manufacturers are challenged to produce multi-function devices of increasingly compact dimensions. Micromolding and multicomponent LSR technologies provide a solution to this issue.

“Extending design options further than any other technology, multicomponent molding enables medical device developers the opportunity to go beyond simple function. Virtually boundless product profiles and geometries offer device designers options that they may not even be aware of.”

Rapid development of custom parts

Trelleborg Healthcare & Medical is a leading exponent of moldings often used in implantable healthcare and medical devices. In-house precision tooling and expertise enable Trelleborg to create custom silicone and thermoplastic molded parts with tight tolerances, while satisfying the need for rapid product development with quick turnaround prototypes. The Rapid Development Center in Delano, Minnesota, in the US, provides Trelleborg’s global healthcare and medical customers with a single partner for design, rapid prototyping, development, and serial production, ensuring cost control and scalability of customers’ solutions.

>>Find out more about the Rapid Development Center

Also featured is Trelleborg’s unique iCast™ digital manufacturing process, an innovation in LSR processing. Involving no tool investment, it offers a cost-effective way to develop product variations or try out different design concepts before investing in serial production. Cutting concept to production time for prototypes from a typical four and a half months to a maximum of three weeks for the average part, it helps manufacturers meet the pressures of rapidly moving markets that demand quicker new product introductions, improvements and advancements.

Trelleborg’s team will also highlight drug delivery technologies including drug-eluting silicone with active pharmaceutical ingredients (API), and the Seal-Glide® nanoscale surface treatment. Compared to conventional solutions, this innovative process improves friction performance and has a surface finish up to 50 times thinner than those solutions.

>>Find out more about drug-eluting products

>>Find out more about Seal-Glide®

For further details regarding Trelleborg’s Healthcare & Medical operations, go to www.trelleborg.com/healthcare.