Custom silicone sheeting and film, manufactured by Trelleborg Healthcare & Medical to meet customer specifications, serves a variety of medical uses:

- Discs punched from vulcanized elastomeric sheets are key components in various types of valve assemblies

- Mesh-reinforced sheeting is integrated as sewing rings on artificial heart valves

- Laminated sheeting containing both vulcanized and unvulcanized layers is used to seal tissue expanders and mammary devices

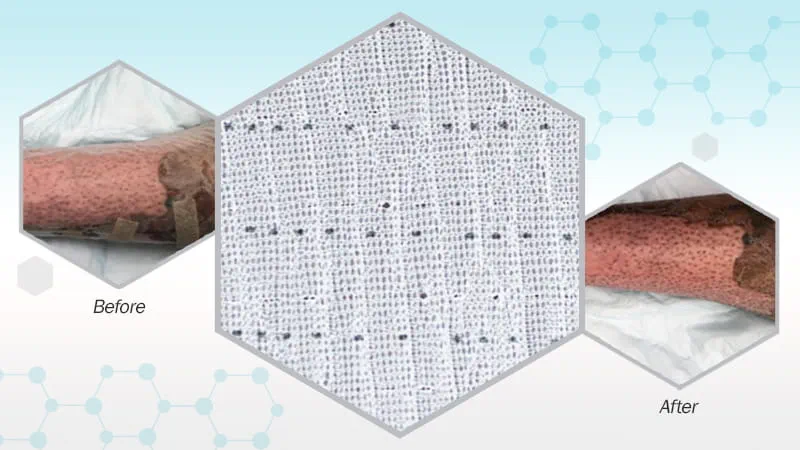

- Our knife coating technology is used to produce custom dermal adhesive gel products for wound management and scar reduction applications

Our silicone sheeting and film has the following characteristics:

- Available in LSR and vulcanized and unvulcanized HCR materials

- Reinforced and non-reinforced options are available

- May be bonded to itself or synthetics (polyester tricot)

- Easily cut to desired shape

- Autoclavable without changes in consistency, softness, or other inherent properties

- Biologically active fluids have little or no effect on the sheeting

- Excellent biocompatibility as evidenced by its USP Class VI clearance

Silicone Sheeting Manufacturing Processes

We produce sheeting using two different methods: