Saving time while being safe

Challenge

Warsop, a parish on the edge of Sherwood Forrest in Nottinghamshire, was planning a new housing estate. Severn Trent Water, a regional state-owned water authority, was responsible for the sewer infrastructure in the area. For this new development, they needed to extend the existing wastewater pipeline and place additional manholes. To limit the disruption to existing traffic, they wanted the job done in the shortest amount of time. However, not at the expense of the workers’ safety in the trenches.

Our activities

In partnership with Tracey Concrete, who provided the concrete pipes and pre-fabricated manholes, Trelleborg supplied the seals that were needed to join the concrete fixtures and provide a watertight seal.

By casting the Trelleborg 165 into the concrete pipe during manufacture, the chance of seals getting displaced or lost during stocking or transportation was eliminated. With no additional steps required at installation, time saved was about 30%.

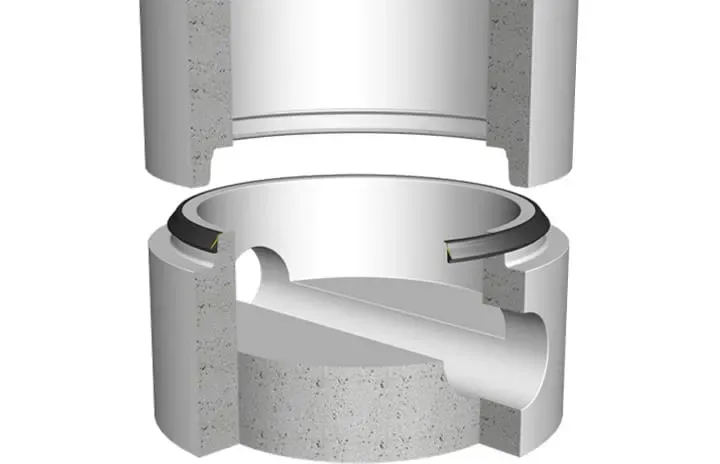

The Trelleborg 118 pre-lube seal is easily stretched onto the spigot of the manhole and the internally lubricated mantel facilitates jointing with a minimum of force. Pre-lubrication also eliminates the potential danger of applying lubricant to the socket of suspended manhole units. This enables a safe working environment.

Product details

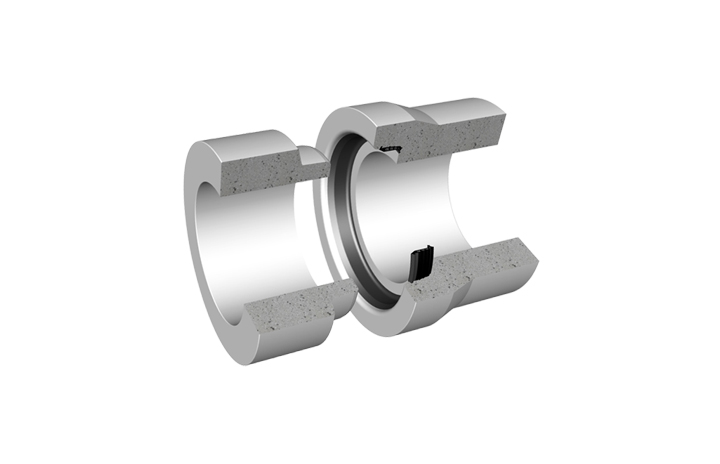

Trelleborg 118 is a pre-lubricated sliding seal, that is stretched onto the spigot of the manhole. Additional lubricant is not required for joint assembly. The seal is designed with a sliding mantle, which is internally lubricated and fully closed to ensure the lubricant stays in place. During installation, the thin mantle slides over the body of the seal.

This design permits installation with very low force, as there is no friction between rubber and concrete. The special design of the joint and seal make the system easy to center during jointing (self-jointing).