Trelleborg Exhibits Innovations in Medical Device Components at Compamed

Accelerating time to market

Attendees can learn about Trelleborg’s new Rapid Development Center. Launched in August 2021 to help healthcare and medical customers bring new products to market faster, the center supports in minimizing production costs, speeding development time, and ensuring superior-quality products.

Chris Tellers, Director of the Rapid Development Center, says: “We have already seen great results for customers utilizing the Rapid Development Center. Our focused capabilities accelerate our customers’ time to market and help them achieve their mission of improving patients’ lives. Using our deep knowledge of polymer materials, excellence in manufacturing, and engineering expertise, the Rapid Development Center delivers increased value to our customers.”

Advanced extrusion technology

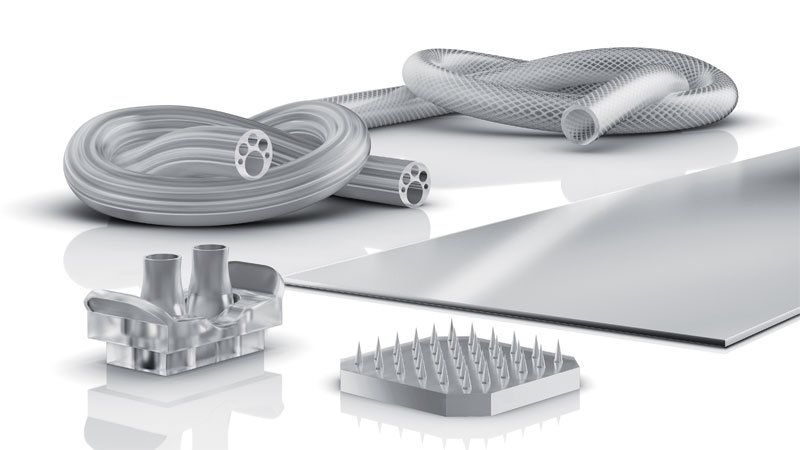

On display will be an extensive selection of Trelleborg’s specialty extruded tubing and hose products. Tubing is available in a full range of sizes and custom-made to meet customers’ individual application needs.

Andrew Gaillard, Global Director of Trelleborg Healthcare & Medical, says: “We engineer novel extrusion solutions for our customers’ specific tube and hosing applications. Examples include multi-lumen, silicone foam extrusions, and kink-resistant tubing for a variety of critical applications such as pacemaker and neuromodulation leads and urological implants. Additionally, Trelleborg’s GeoTransTM technology enables the production of extrusion profiles that can change throughout the length of the extrusion, supporting unique, customer-specific designs.”

State-of-the-art molding capabilities

Trelleborg Healthcare & Medical is a leading exponent of moldings often used in implantable healthcare and medical devices. Utilizing in-house precision tooling and expertise, Trelleborg creates custom silicone and thermoplastic molded parts with tight tolerances, while satisfying the need for rapid product development with quick turnaround prototypes. Attendees will be able to explore Trelleborg’s advancements in multicomponent and micromolding capabilities.

Gaillard says: “One of our most well-accepted capabilities is the combination of Liquid Silicone Rubber (LSR) with plastics. Commonly referred to as 2C or 2-shot, multicomponent injection molding allows our LSR experts to employ highly sophisticated tool and process engineering to develop innovative solutions that combine two or more individual materials into one fully bonded, robust component.”

Drug-device combination products

Trelleborg will highlight the continued evolution of technologies enabling the development of pioneering solutions for patient care including its sheeting and drug delivery capabilities.

“In recent years, we’ve seen a spike in demand from our customer-partners for devices that incorporate an active pharmaceutical ingredient for targeted delivery of a therapy. Whether challenged with a wound-care application that requires wafer-thin silicone gel films with a drug element incorporated, or an innovative approach to cancer treatment with unique manufacturing challenges, our engineering teams are ready to partner with customers to help solve interesting and complex problems,” concludes Gaillard.

>> Contact us to discuss how we can support with your medical device development