Why China needs futureproof solutions for water loss?

China’s drinking water loss is 20 percent due to breaks and leaks in the urban areas’ outdated water networks, primarily made up of ductile iron systems.

However, there is a more sustainable piping alternative when the cities’ networks are up for renewal.

“Whichever way you look at it, 120 billion cubic meters is an enormous waste.” Martijn Boerma, Business Development Manager, Trelleborg.

While China’s urbanization continues at a rapid pace, China’s swelling cities are putting significant strain on local infrastructure and resources. For example, in Shanghai the pollution of waterways is a growing problem. A recent city-wide census found that just 3 percent of the city’s water is clean enough to drink or to use for aquaculture.

While China has enough fresh water to meet its overall needs, more than 80 percent of this is located in southern China, often leaving northern regions such as Beijing, under-resourced.

“However, many of the drinking water networks in big Chinese cities are now constantly being renewed,” says Martijn Boerma, Business Development Manager at Trelleborg’s Asia-Pacific pipe seals operation.

China’s average non-revenue water (NRW) ratio, a key measure of water loss and leakage in the distribution network, is estimated at 20 percent across the country by the Chinese Waterworks Association, and at just 10 percent for the best-performing utilities.

“An NRW ratio of about 20 percent is certainly not extreme compared to other countries. However, as a nation, China’s annual drinking water consumption amounts to around 600 billion cubic meters. Whichever way you look at it, 120 billion cubic meters an enormous waste,” says Boerma.

Breaks and leaks in the water network’s pipes are normally the leading causes of water loss. In China, the water networks are primarily made up of traditional ductile iron (DI) systems. As China’s urban population has grown over the past decades, years of prolonged strain have resulted in cracks and breakages in the pipes.

Local municipalities and network owners face critical decisions regarding pipe repair and replacement, including over which materials to use. As well as reliability and product duration, there are questions surrounding maintenance, sustainability and energy use to consider.

An alternative to the traditional DI pipes, plastic high-density polyethylene (HDPE) pipes, has emerged over the past couple of years for their affordability and durability.

However, these solutions may not represent the most practical choice for an increasingly resource-conscious economy like China. For one thing, the increased wall thickness of HDPE pipes means more material and energy is consumed during manufacturing and transportation, while fusing, or welding, HDPE joints requires specialist skills that may not be available in more remote areas.

There is, though, another alternative. Compared with HDPE, the molecularly oriented polyvinyl chloride (PVC-O) pipes offer network owners a number of advantages.

“PVC-O is a lighter, stronger, greener and more durable alternative which also uses less material,” says Boerma.

PVC-O pipes have many advantages compared to the rival piping solutions, DI and HDPE, not least when it comes to sustainability:

- Less energy is consumed during the production, transport, and installation of the pipe

- The pipe’s thin, smooth walls lead to increased hydraulic capacity, which in turn leads to reduced energy being consumed during the pipe’s operation

- PVC-O’s enhanced strength and resistance requires less raw material to be used

- PVC-O pipes have a longer service lifetime, again due to the material’s superior material qualities, including low creep and deformation when subjected to chronic strain

In fact, the overall energyconsumption and carbon dioxide (CO2) footprint of PVC-O is estimated to be much lower compared to HDPE and DI pipes.

The relative ease of transporting, installing and joining PVC-O pipes is also advantageous for more remote cities located beyond the country’s economic heartland.

Similarly, PVC-based water systems are relatively easy to lay in the ground, alleviating the need for specialist installers and reducing the potential for human error that can lead future breaks and leaks.

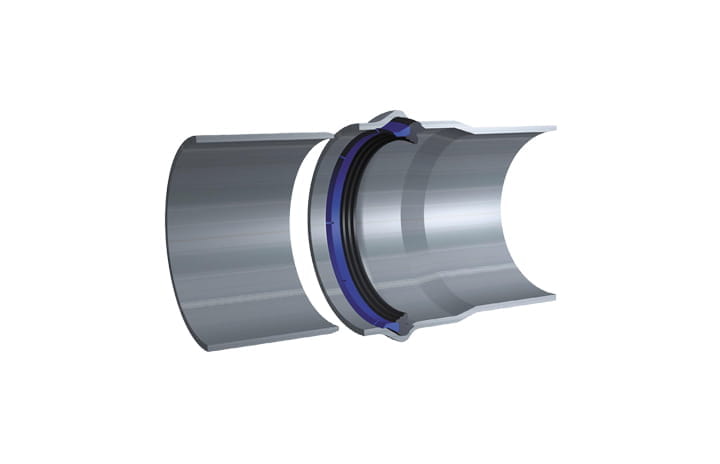

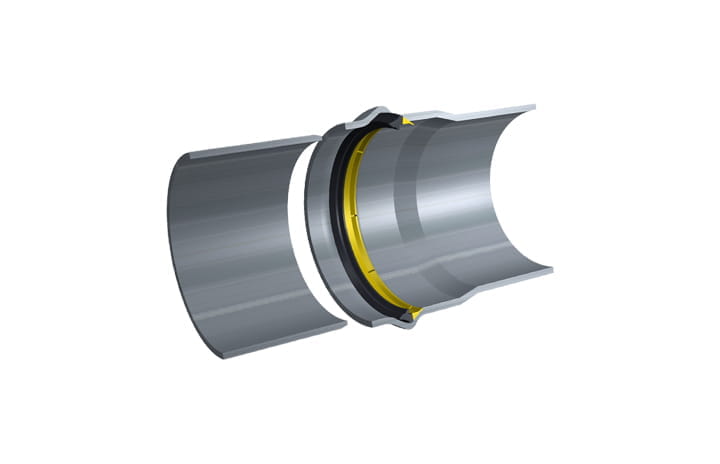

“Trelleborg produces seals that fit PVC-O pipes in facilities in Europe, the US, and Asia, and we supply on a global scale,” says Boerma.

A true watertight seal