Seal design & function

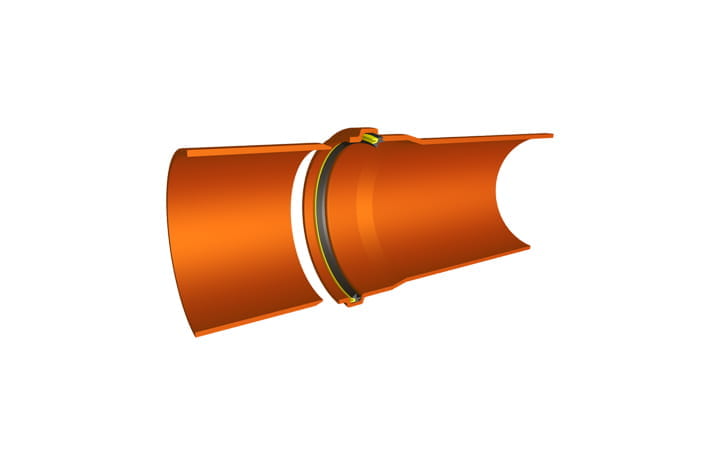

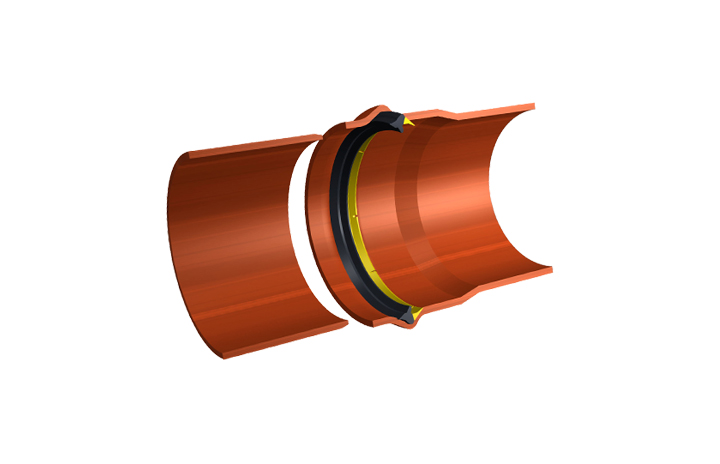

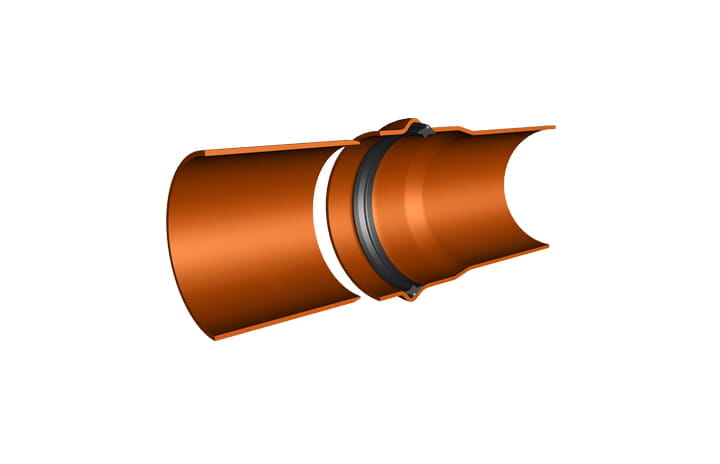

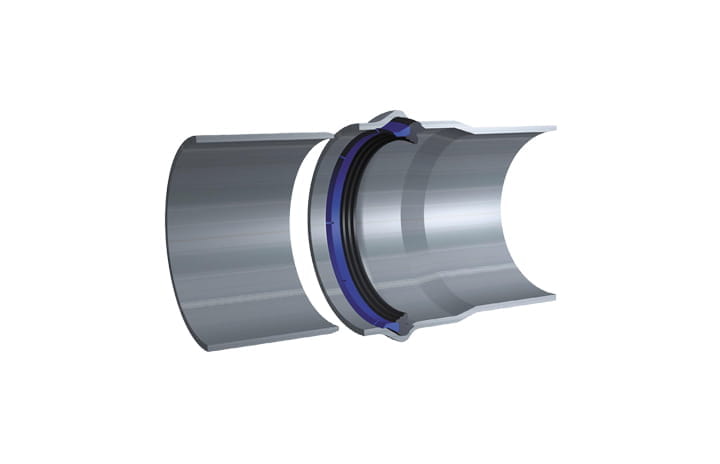

Trelleborg 582 Din-Lock is a combined lip and compression seal. Installed inside the socket after it has been formed, the retaining element effectively locks the seal into the groove.

Making the seal an integral part of the pipe brings many advantages: rings can no longer get lost during stocking and transportation, and the low jointing force ensures that the seal stays in place when pipes are jointed.

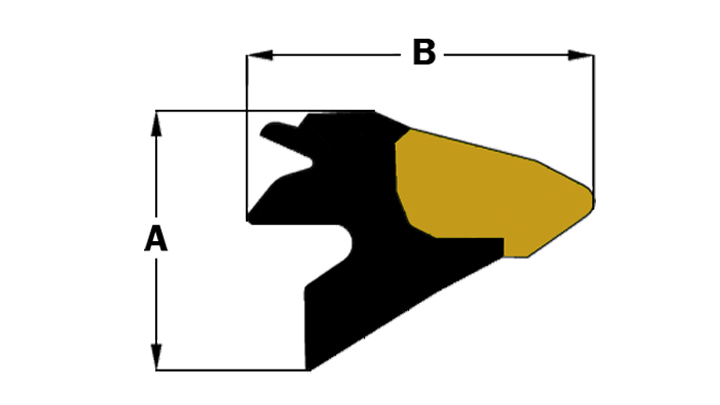

The unique design comprises of two elements: a plastic retaining element that holds the seal securely in position and a rubber sealing element that ensures a watertight seal once the pipes are jointed. Together, they absorb any permissible variations in the groove.

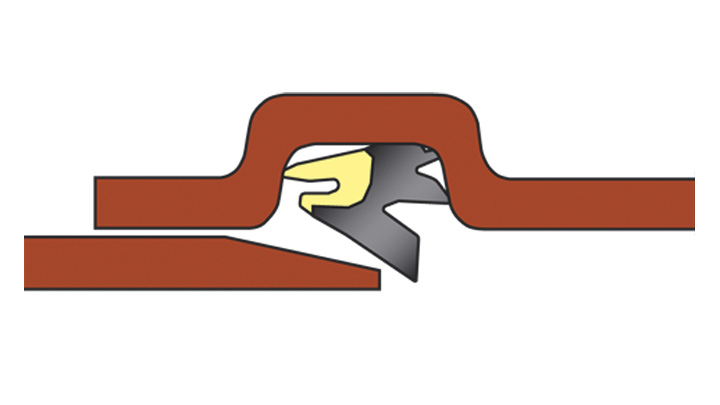

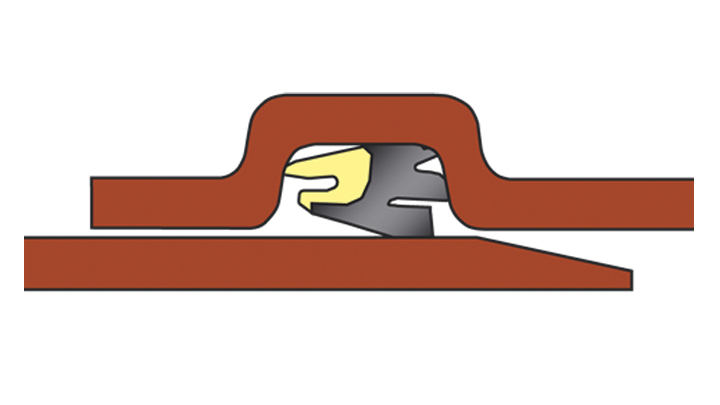

How to insert a Din-Lock

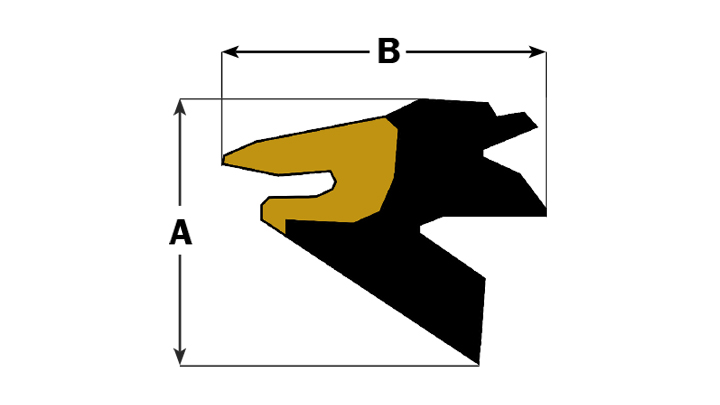

Sizing Chart

582 Din-Lock (mm)

| PIPE SIZE (mm) | A (mm) | B (mm) |

|---|---|---|

| 50 | 7.2 | 9.9 |

| 75 | 7.2 | 9.9 |

| 82 | 6.9 | 9.1 |

| 100 | 7.6 | 10.1 |

| 110 | 8.6 | 10.5 |

| 125 | 10.4 | 11.8 |

| 160 | 11.4 | 13.6 |

| 200 | 11.4 | 15.3 |

| 250 | 16.5 | 23.8 |

| 315 | 19.6 | 19.4 |

| 400 | 20.8 | 21.6 |

| 500 | 25.6 | 28.0 |

589 Din-Lock (inch)

| PIPE SIZE (Inch) | A (Inch) | B (Inch) |

| 4 | 0.338 | 0.449 |

| 6 | 0.338 | 0.449 |

| 8 | 0.449 | 0.667 |

589 Din-Lock (mm)

| PIPE SIZE (mm) | A (mm) | B (mm) |

|---|---|---|

| 4 | 8.6 | 11.4 |

| 6 | 8.6 | 11.4 |

| 8 | 11.4 | 17.0 |