Seal design & function

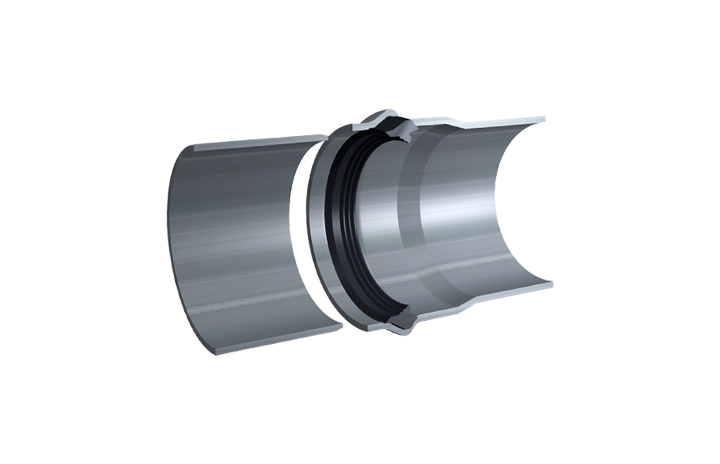

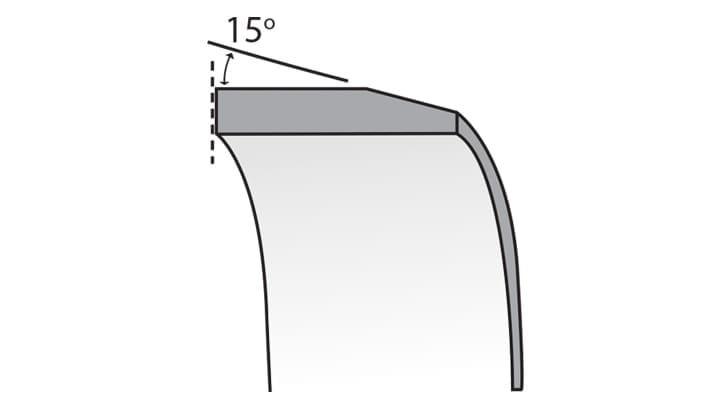

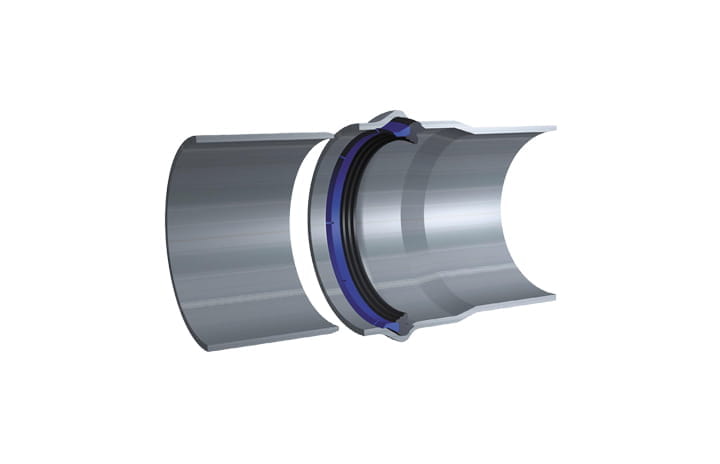

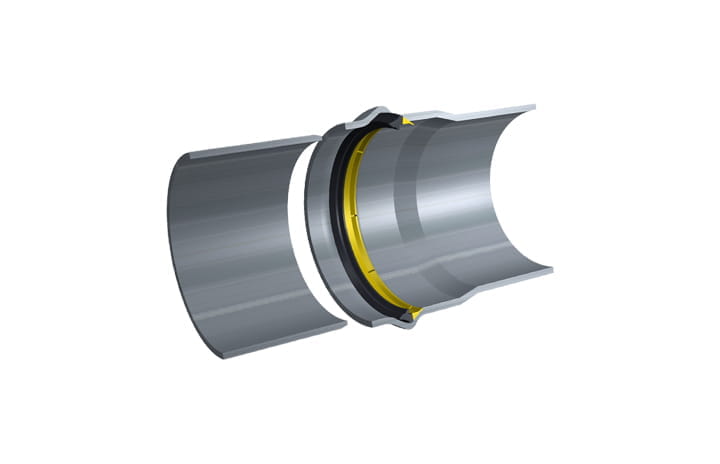

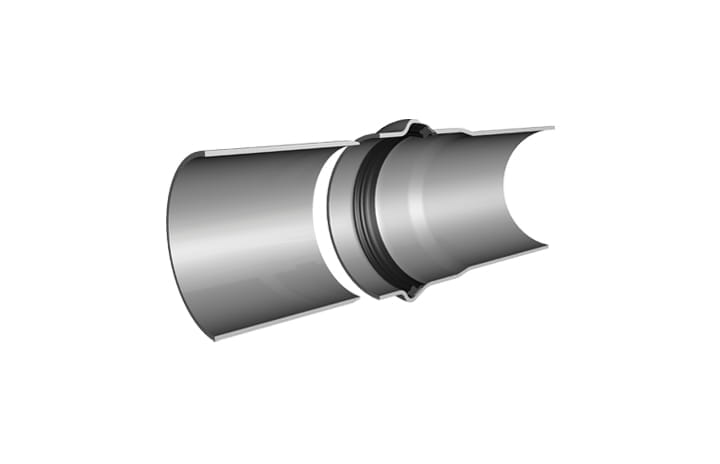

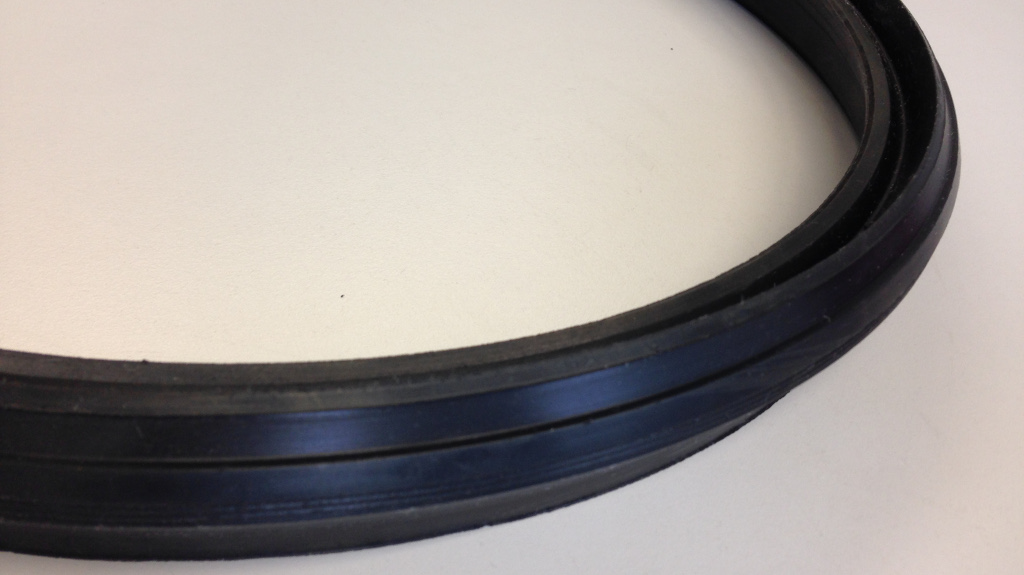

The Trelleborg 575 Anger seal is a combined lip and compression seal. The seal is positioned in the socket by the pipe manufacturer.

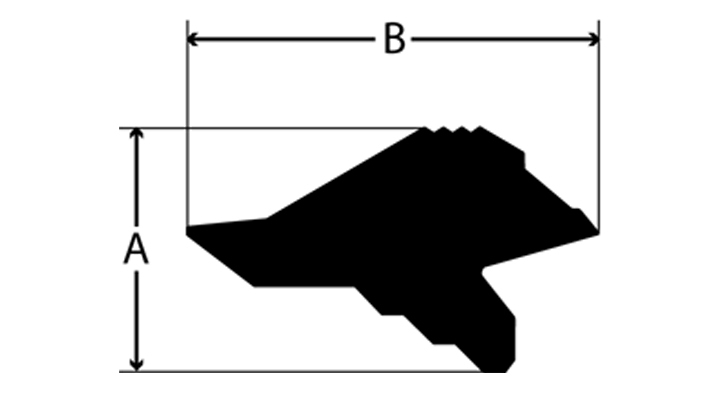

The ”main lip” comprises a combined lip and compression section. The ”front and rear lip” locates the seal in the socket groove and absorbs any permissible variations in the groove.

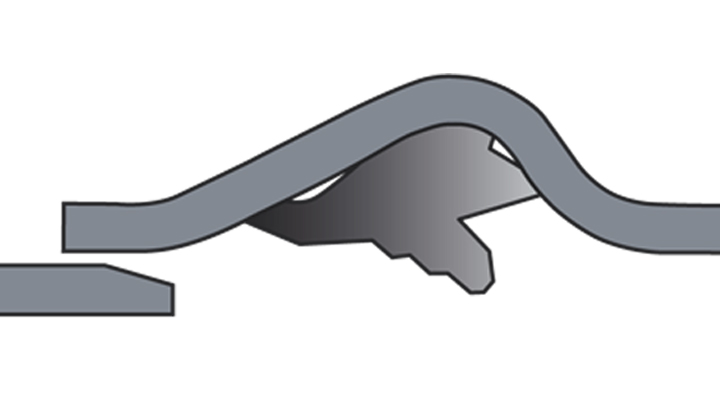

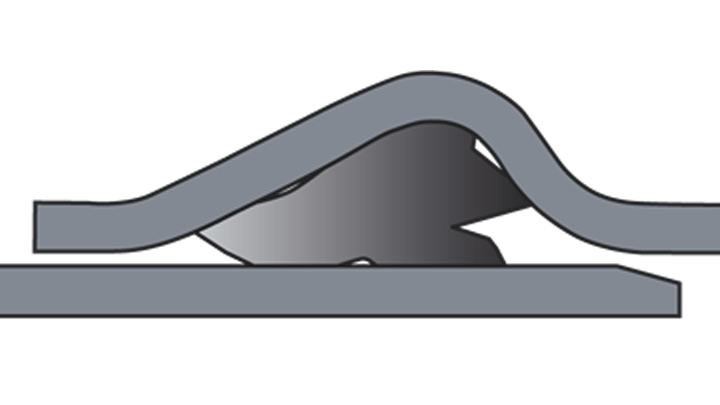

The Trelleborg 575 Anger seal meets or exceeds current European standards for both pressure and vacuum, deflection and shear load. Furthermore, the seal design gives low assembly forces making pipe jointing.

Automatic seal insertion

Sizing Chart

| PIPE SIZE (mm) | A (mm) | B (mm) |

|---|---|---|

| 63 | 10.4 | 17.7 |

| 75 | 11.6 | 19.6 |

| 90 | 12.7 | 21.5 |

| 110 | 13.8 | 23.4 |

| 125 | 13.8 | 23.4 |

| 140 | 14.8 | 25.1 |

| 160 | 15.9 | 27.0 |

| 200 | 16.9 | 28.7 |

| 225 | 18.0 | 30.6 |

| 250 | 19.9 | 33.8 |

| 280 | 21.2 | 36.0 |

| 315 | 22.2 | 37.7 |

| 400 | 28.0 | 44.8 |

| 500 | 32.2 | 51.5 |