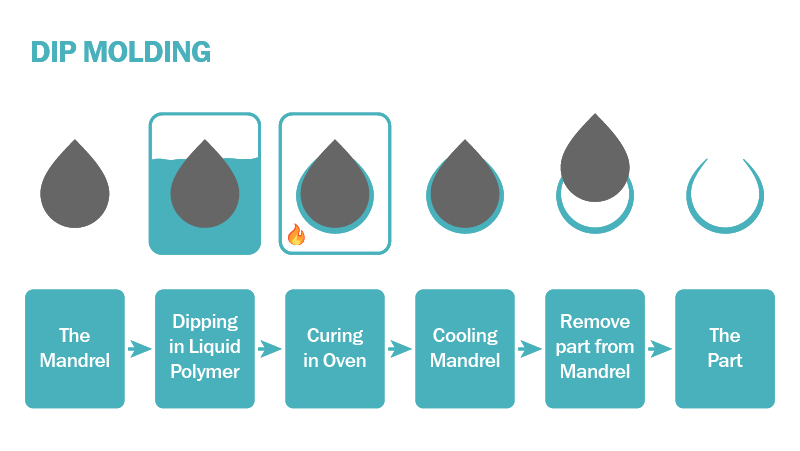

Dip Molding

- Cured silicone takes exact form of mandrel

- Control for thickness, layers, and other variables

- Great flexibility in manufacturing

- Quick prototypes for simpler mandrel geometries

- Cost effective at lower volumes – low setup costs

Step 1: Produce a mandrel in the shape of the final part. Mandrels can be machined from metal, engineered plastics or ceramics.

Step 2: Immerse the mandrel into the silicone dispersion. Once withdrawn, the mandrel is coated with a thin liquid silicone film.

Step 3: The silicone-coated mandrel is placed in an oven to vulcanize.

Step 4: The silicone rubber is stripped from the mandrel creating the finished product.

Step 5: Process validations.

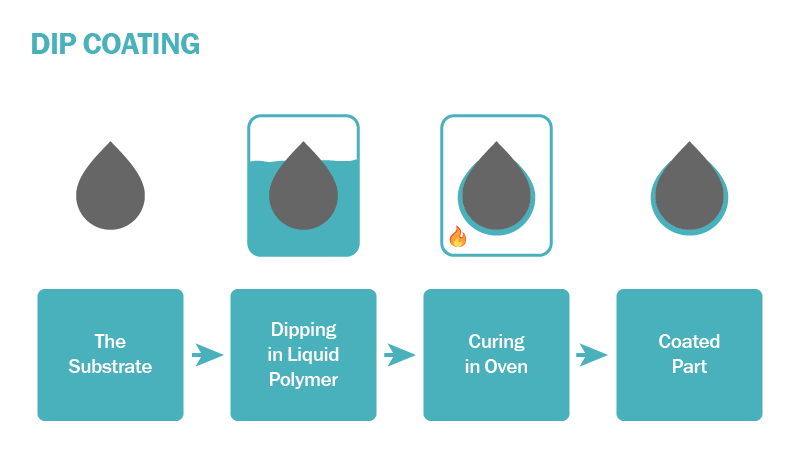

Dip Coating

Dip coating improves the effectiveness of medical devices. It can be done in high volumes with quick throughput, allows for fast prototyping, and has the potential for variations including the number of dip coats and using a heated or unheated mandrel.

Some secondary operations for dip coated products include heat shrinking, assembly, and packaging.

Benefits of Dip Coating

For electrosurgical scalpels:

- Deliver precise cutting performance by directing cutting arc through thinnest coating edge

- Reduce eschar adhesion and buildup to facilitate cleaning and use fewer electrodes

- Allow electrode to bend up to 90° without compromising integrity of electrode or coating

- Reduce friction/pain for hypodermic needles and scalpels

- Encapsulate sensors for improved biocompatibility

- Increase a surgeon’s grip on device handles

Plastic and metal medical components can be coated with thin silicone films and then vulcanized to produce a smooth, durable, and biocompatible finish. Medical cutting surfaces such as needles and scalpels can be coated with a thin film to reduce surface friction and insertion pressures to enhance patient comfort.