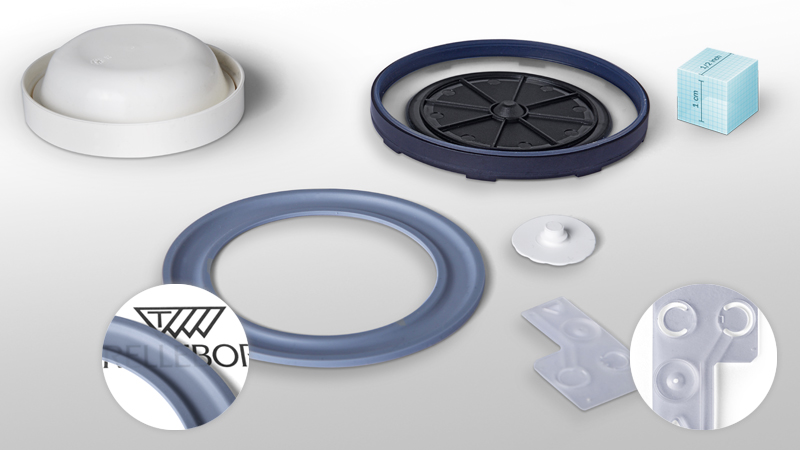

Unlimited design capabilities

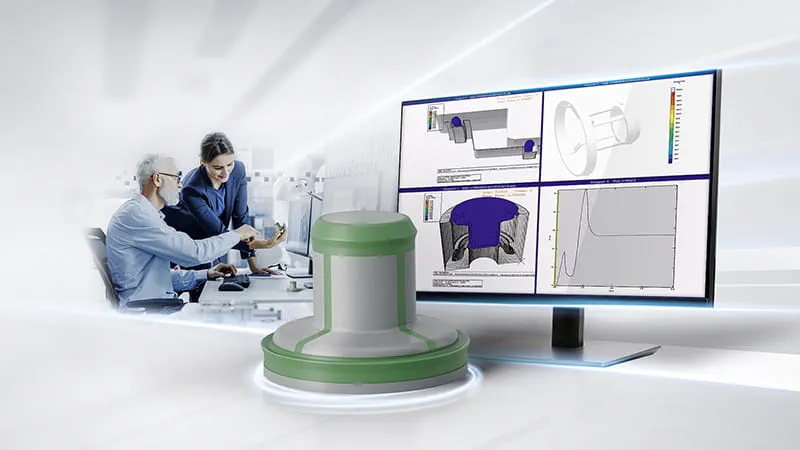

We rely on in-house tooling and sophisticated process engineering to improve quality and ensure the consistent achievement of tight tolerances while delivering the lowest cost of ownership for our customers.

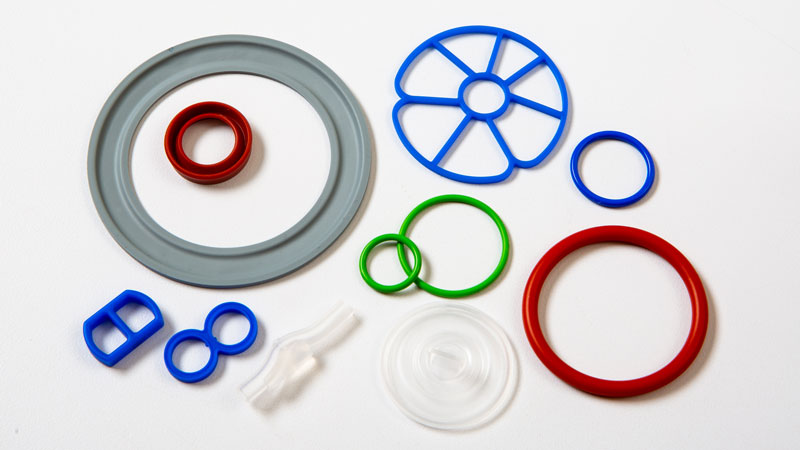

Silicone Injection Molding Special Capabilities

Applications

LSR injection molding is an ideal production method for a range of medical products. Applications include drug delivery, such as primary drug packaging or wearable smart drug pump systems, fluid management, diagnostics, and biotechnology.

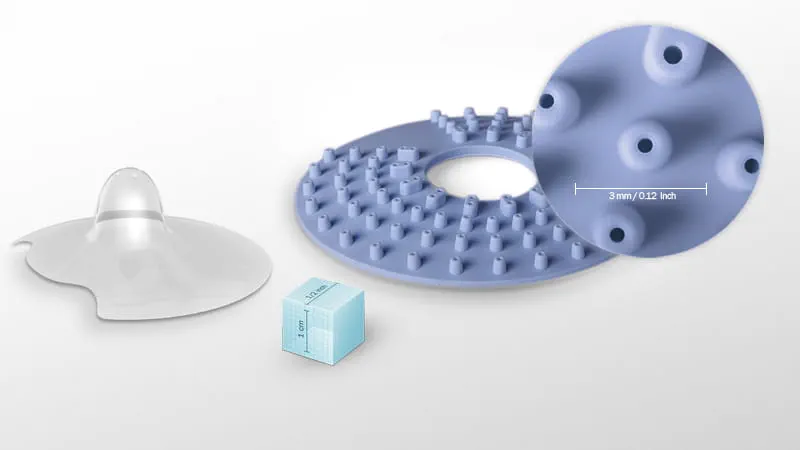

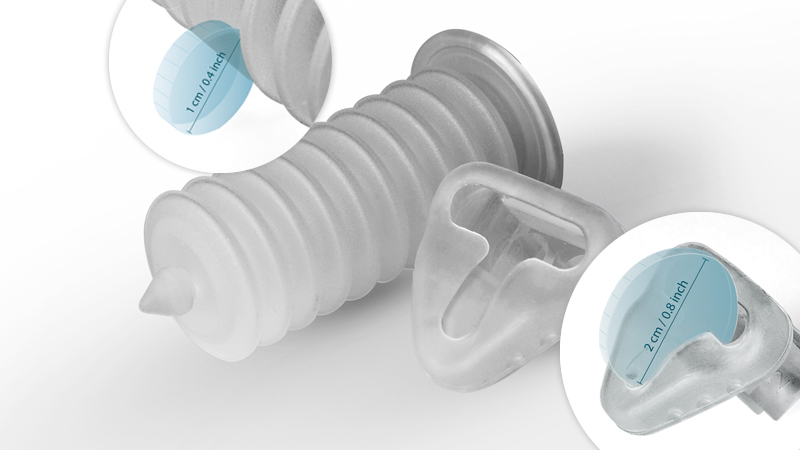

Perfect flash-free molding is essential in some of the parts produced in Liquid Silicone Rubber (LSR) such as nipple protectors produced for nursing mothers.

Automation meets super clean requirements

The nipple protector is produced in a cleanroom to prevent its high gloss finish from being blemished by airborne particles. The part cannot be manually handled, as the slightest fingerprint would spoil its crystal-clear finish. Therefore, the nipple protector is removed robotically from the tool and placed on a belt feeder that takes the product through post-cure and straight into the box in which it is shipped.

Timing between the process steps is perfectly aligned to have a continuous process flow. The part must be flashless, as any flash at the nipple shield hole would prevent effective milk delivery from a nursing mother.