Applications

Extraction and transport hose for bulk abrasive products for the food industry (sugar, grains, flour, milk powder, cattle feed, etc.) and chemicals (PVC, dry stuffs, etc.).

Advantages

Can be used in ATEX areas: 0, 1, 2 and 20, 21, 22.

Non-marking, abrasion resistant cover.

Conductive tube and cover considerably extend service life especially for transfer at high speeds.

Design

Overview

Inner tube

foodgrade abrasion resistant NBR, smooth, white,

Reinforcement

synthetic textile with embedded steel helix,

Cover

wear and weather resistant NBR/PVC, corrugated, green,

Temperature range

-10 to +80

Electrical properties

conductive tube and cover,

R<100MΩ/lg, helix must be connected with couplings.

R<100MΩ/lg, helix must be connected with couplings.

Standard/Approval

EU regulations No. 1935/2004, 2023/2006.

FDA regulation No. 21 CFR 177.2600.

French legislation.

All relevant migrations tests (France and FDA) were performed by the French institute of Poitiers (IANESCO) and confirmed compliant.

FDA regulation No. 21 CFR 177.2600.

French legislation.

All relevant migrations tests (France and FDA) were performed by the French institute of Poitiers (IANESCO) and confirmed compliant.

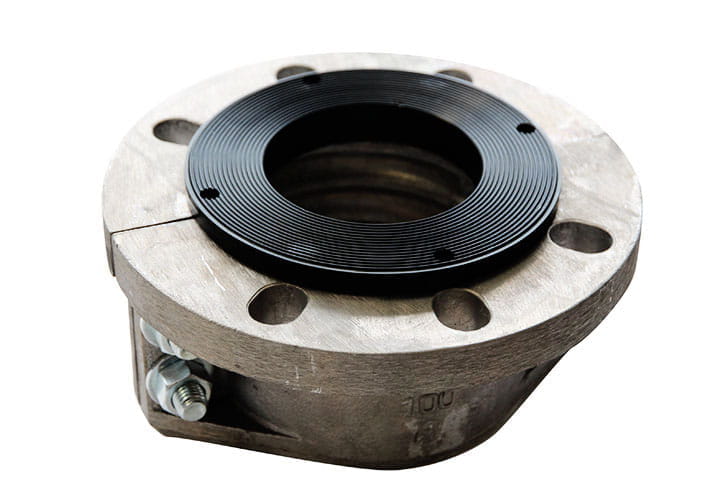

Couplings Fittings

Hoses are fitted with BLOC-END® and must be used to the following maximum working pressure: 10bar.

Technical Specifications

| ID (mm) | Wall thickness (mm) | OD (mm) | Working Pressure (bar) | Bursting pressure (bar) | Max. vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Article number | Stock or min. order (m) |

¤ Upon availability. * Tolerance on length: ± 1 % (ISO 1307 Standard)

Downloads