Applications

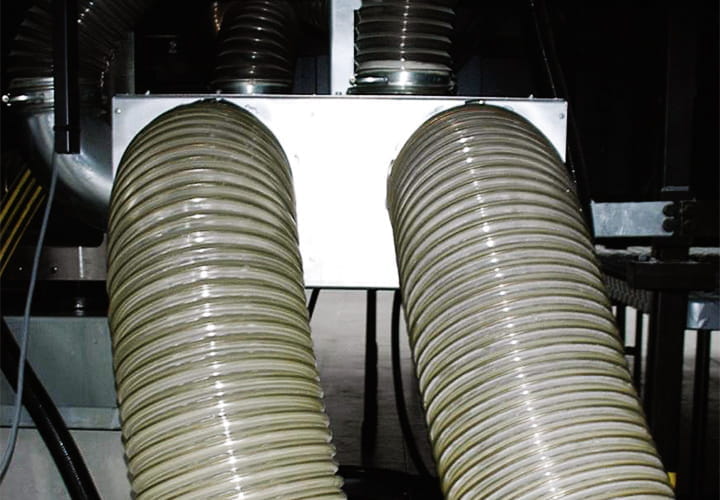

A highly flexible and robust ducting.

For use in many industries such as metallurgy, wood working, food, pharmaceutical industries.

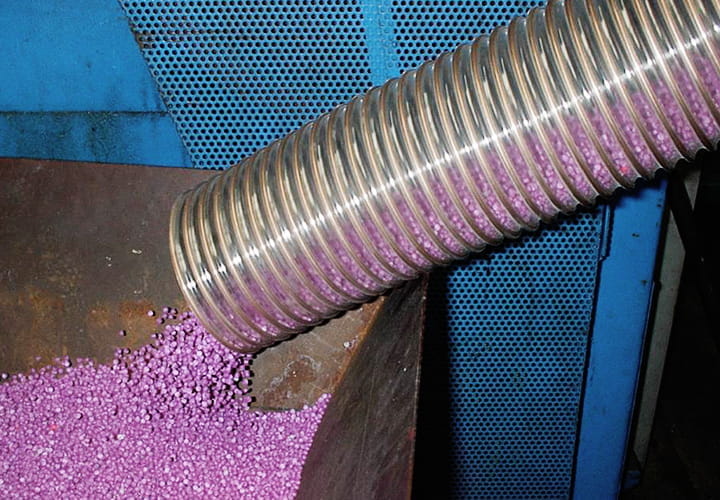

Ideal for the conveyance of grains, granules, sawdust and wood chips, metal filings in humid and/or warm conditions.

Specially suitable for street vacuum cleaners and lawn mowers. Flame retardant according to DIN4102B1 or antistatic material in option.

Advantages

Light and easy to handle.

Non toxic food grade polyurethane resisting to hydrolysis and microbiological attack.

Outstanding resistance to abrasion and piercing.

Excellent mechanical flexibility due to perfect cohesion of components (PVC-coated spring steel helix welded to polyurethane wall).

Smooth inner tube ensures optimum flow.

Good resistance to ozone and ultraviolet light.

Good resistance to most of oils, solvents, and industrial chemicals in the vapour phase at moderate concentration.

Design

Technical drawing

Overview

Reinforcement

white PVC-coated steel helix,

Temperature range

-30 to +100

Electrical properties

Standard: non conductive.

Option antistatic, R<10^8Ω/m: consult us.

Option antistatic, R<10^8Ω/m: consult us.

Special properties

Abrasion ISO 4649: 40mm3.

Option flame retardant, DIN 4102B1: consult us.

Halogen and plastiziser free.

Option flame retardant, DIN 4102B1: consult us.

Halogen and plastiziser free.

Standard/Approval

Food contact: EU regulation 10/2011/CE.

Additional information

Technical data for working conditions at 20°C temperature.

Couplings Fittings

Standard: connexion by clamp.

Technical Specifications

| ID (mm) | Wall thickness (mm) | OD (mm) | Working Pressure (bar) | Bursting pressure (bar) | Max. vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Article number | Stock or min. order (m) |

¤ Upon availability. * Tolerance on length: ± 1 % (ISO 1307 Standard)