Applications

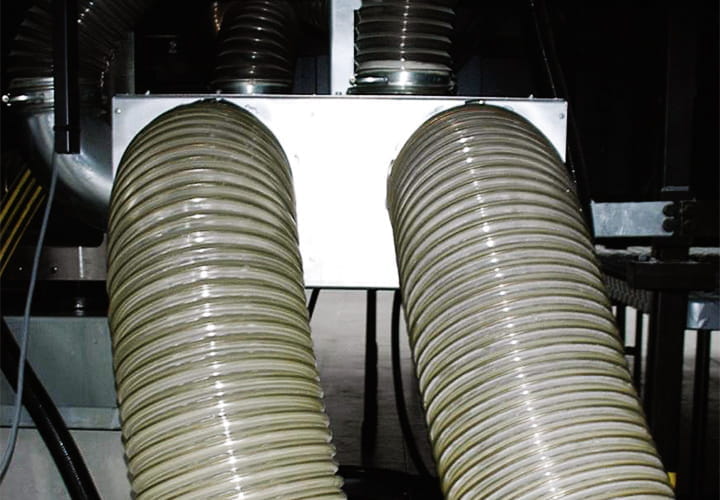

Food grade ducting, very smooth.

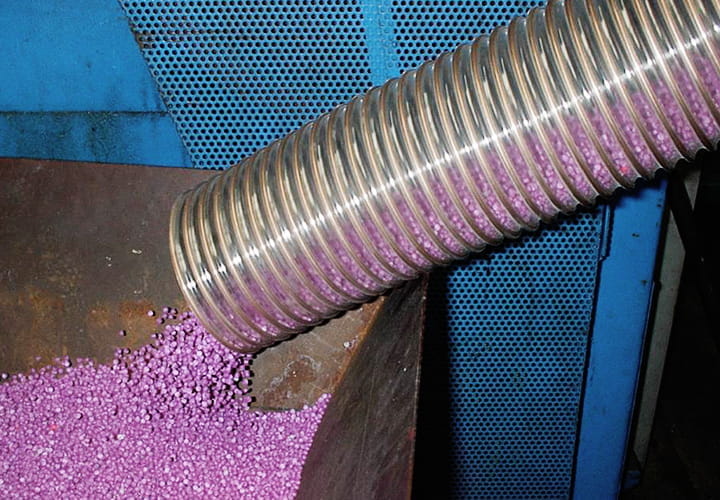

Ideal for suction and transport of abrasive materials, powders and granules in food industry, drugs in pharmaceutical laboratories.

Industrial vacuum cleaners and floor care applications, lawn mowers and rock wool projection.

Wood working industries.

Wire conduit for robotics, X-ray machine.

Advantages

Food grade polyurethane.

Good resistance to abrasion, piercing and impacts.

Outstanding flex-resistance, thanks to the bonding of the PVC helix and polyurethane wall.

Very resistant to hydrolyze and micro-biological attacks.

Light, flexible at low temperature. Smooth inner liner ensures optimum flow.

Good resistance to ozone and UV.

Good resistance to many oils, solvents, industrial chemicals in the vapour phase at moderate concentration.

Design

Technical drawing

Overview

Reinforcement

hard PVC impact resistant helix embedded in the polyurethane wall,

Temperature range

-30 to +80

Electrical properties

Non conductive.

Option: copper string PVC-coated to obtain electric equipotentiality.

Option: copper string PVC-coated to obtain electric equipotentiality.

Special properties

Abrasion ISO 4649: 40mm3.

Food grade quality.

Food grade quality.

Standard/Approval

EU regulation 10/2011/CE.

Additional information

Technical data for working conditions at 20°C temperature.

Couplings Fittings

Standard: connexion by clamp.

Option: can be screwed into the couplings.

Option: can be screwed into the couplings.

Technical Specifications

| ID (mm) | Wall thickness (mm) | OD (mm) | Working Pressure (bar) | Bursting pressure (bar) | Max. vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Article number | Stock or min. order (m) |

¤ Upon availability. * Tolerance on length: ± 1 % (ISO 1307 Standard)