Trelleborg’s highly engineered hollow shells, reduce weight in composite or syntactic materials, without compromise. With our unique engineering ability, we pick up where traditional glass microspheres filler stops.

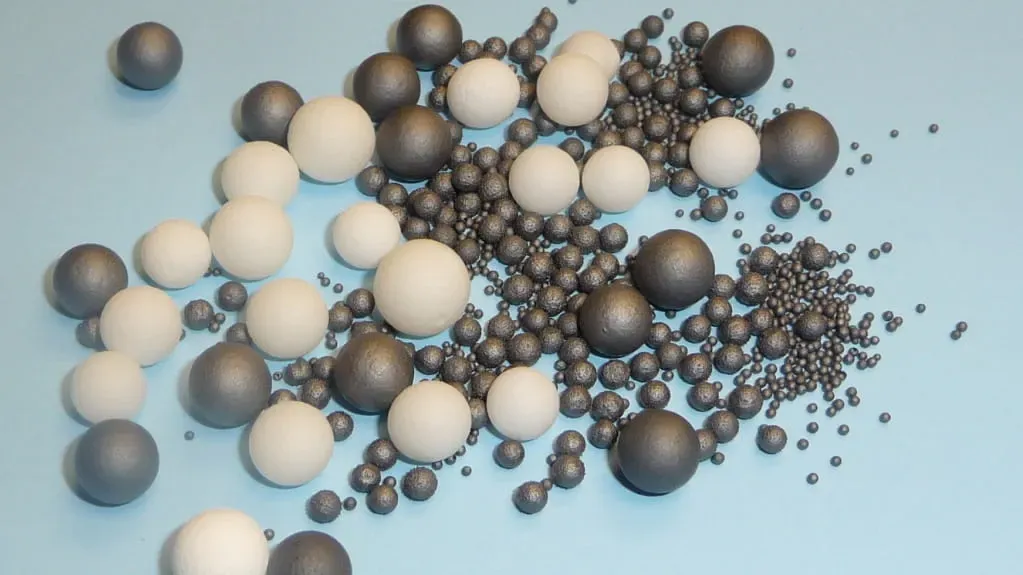

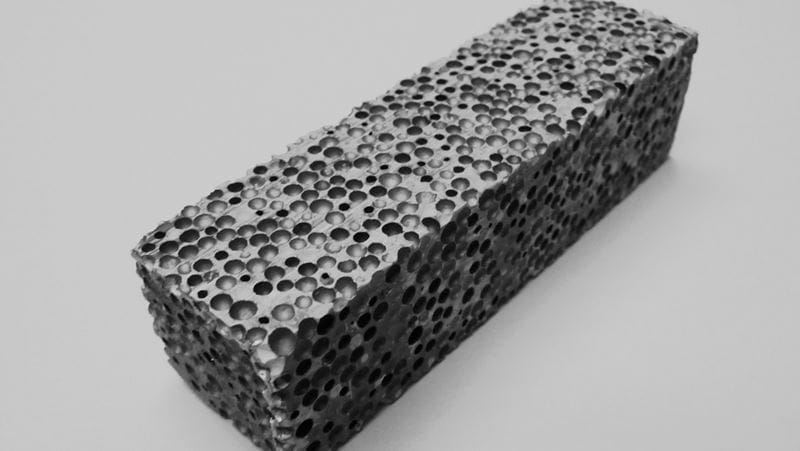

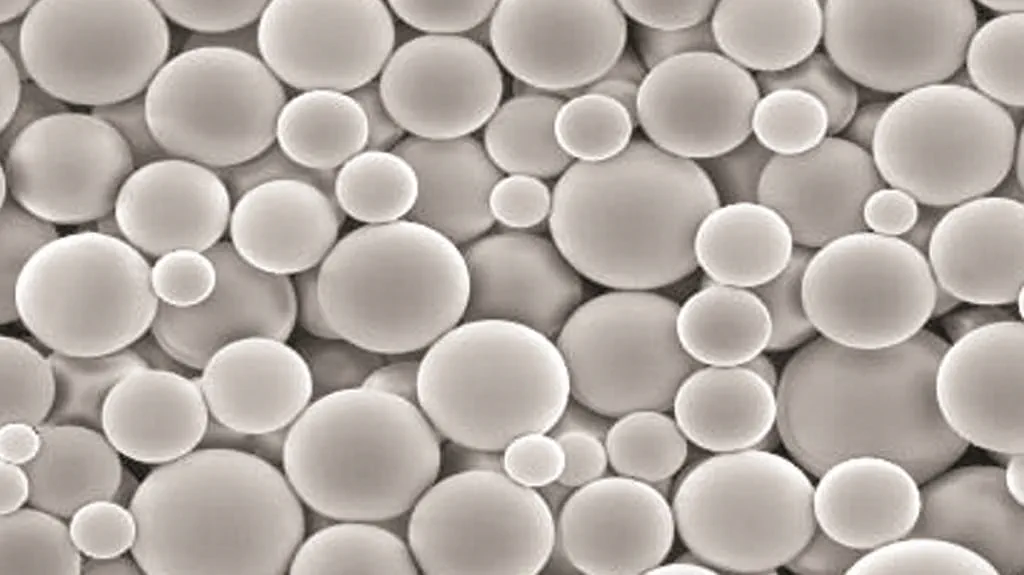

Trelleborg's proprietary processing techniques allow the fabrication of hollow shells made of unconventional materials such as ceramic and metal. Our custom and stock Hollow Shells will increase your design space and allow you to achieve mission-critical performance where it counts. Let us help you make your product or material lighter, stronger, more shock absorbent, and fireproof.

Tailored or standard stock

Tailored surface finish (rough or smooth)

Suitable for use at high temperatures

Hydrostatic crush strengths over 20KSI

Lightweight & ductility

Wide range of materials available

Wide range of shapes and sizes

Buoyancy

Defense

Medical

Power generation plants

Space equipment