Trelleborg Fluid Handling Solutions

With over 1,500 employees, located in Europe, Turkey, Australia and China, Trelleborg Fluid Handling Solutions is a key supplier focusing on fluid handling technologies as well as material protection in demanding areas.

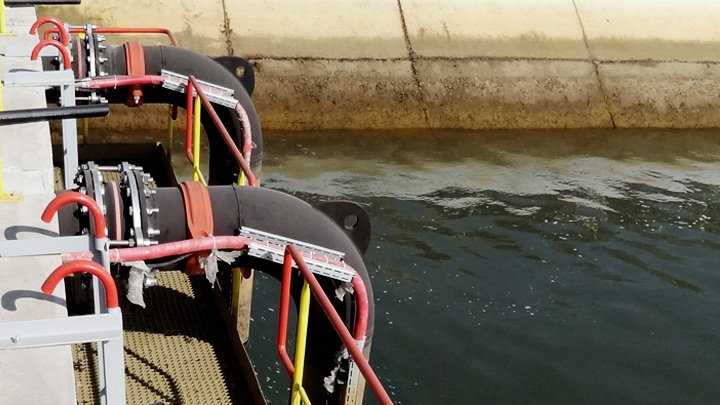

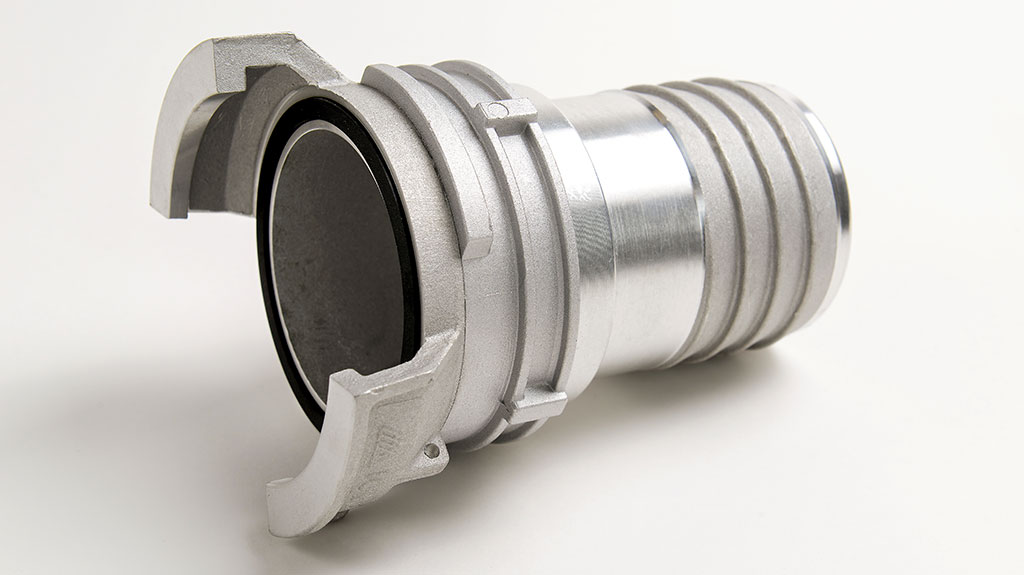

The Trelleborg Fluid Handling team provides high performance solutions for oil and gas transfer for marine applications, fluid handling systems in the industrial applications and full material and equipment protection in the mining industry.

The Trelleborg Fluid Handling team provides high performance solutions for oil and gas transfer for marine applications, fluid handling systems in the industrial applications and full material and equipment protection in the mining industry.

Videos

Discover all our know-how in videos and even more videos here

Hose assemblies solutions for Building & Construction

Trelleborg provides builders with the widest hose assemblies solutions: : deep foundations, concrete piles, compressed air shotcrete, tunnel concrete sprayer, concrete pumping, concrete skips, tunnel slurry.

Agricultural Hoses

This video displays our hose and hose assembly solutions for spraying, irrigation, spreading, in open fields as well as in greenhouses.

Wear Protection for the Mining and Mineral Processing Industry

We engineer and transform polymer and ceramic material science into the most advanced durable wear solutions that seal, damp and protect Mining and Mineral Processing Plant from slurry and impact abrasion.

Tools & Services

Latest innovations, case stories, Q&A