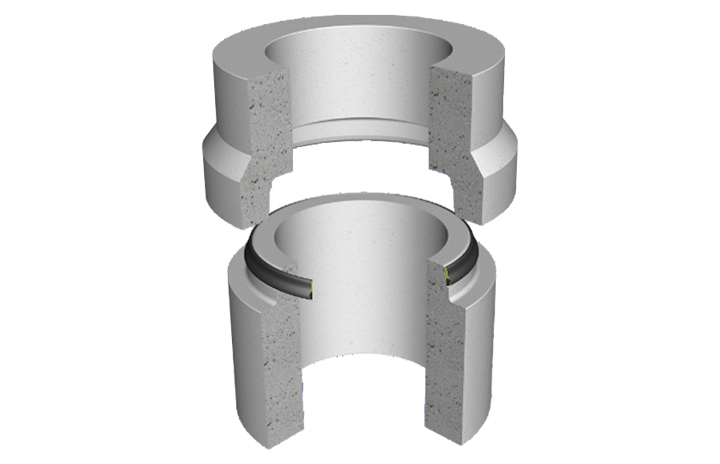

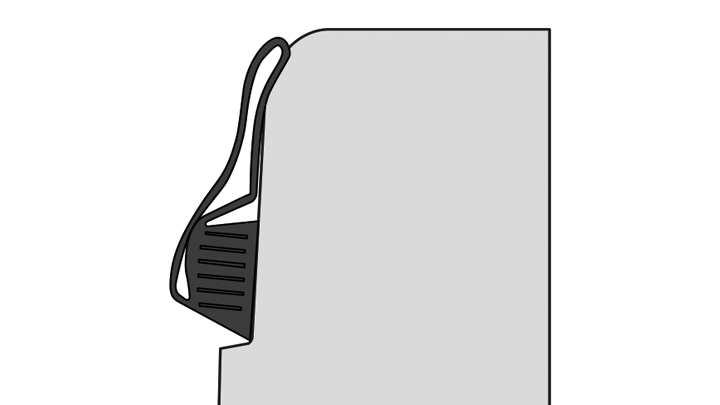

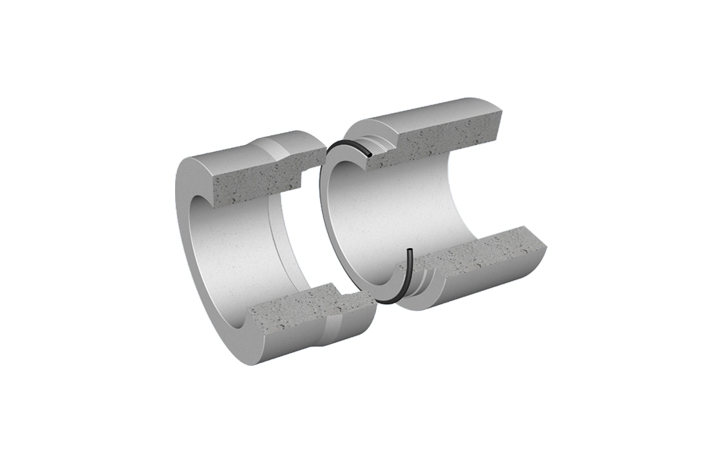

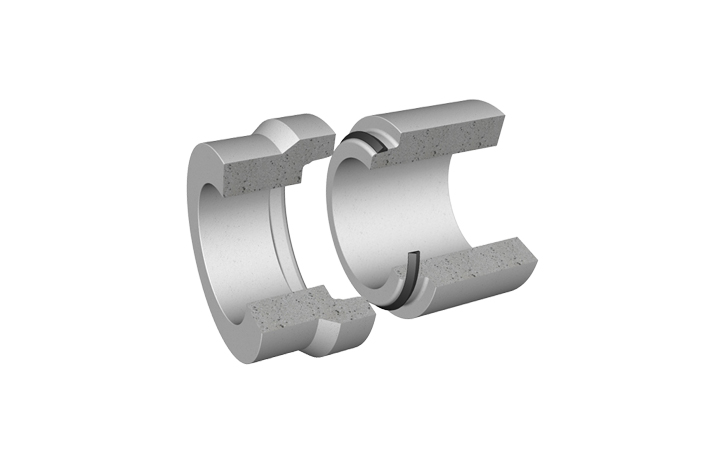

Trelleborg 140 Lamell is a pre-lubricated sliding seal that is stretched onto the spigot of the pipe or manhole. Additional lubricate is not required for joint assembly.

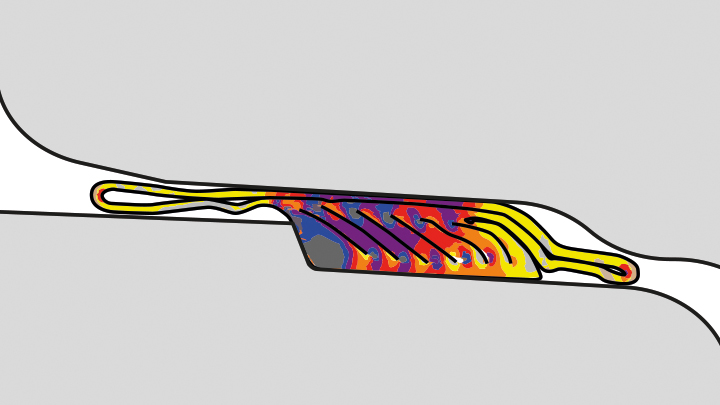

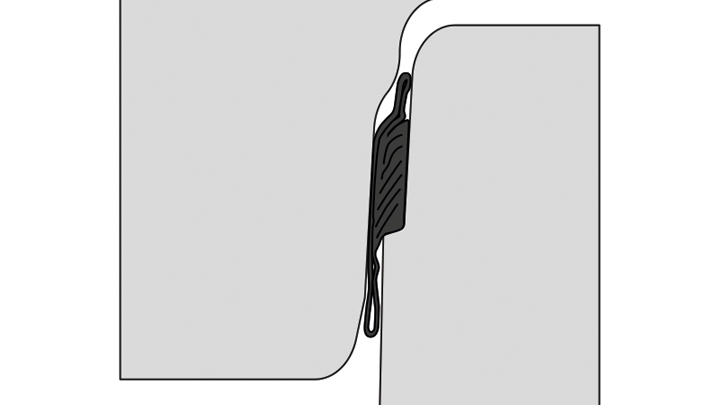

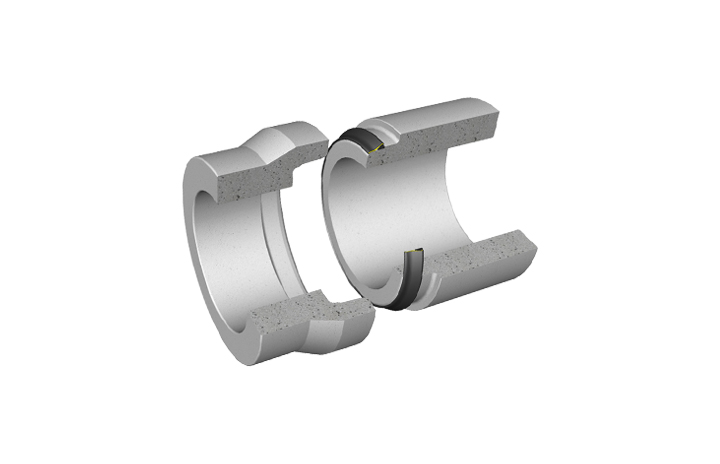

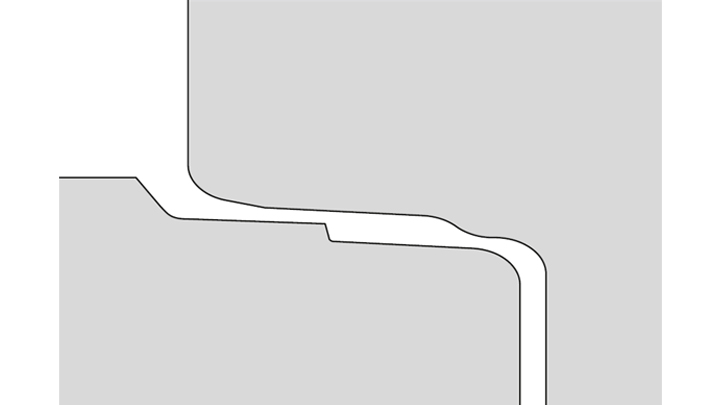

It is designed so that the pre-lubricated mantle rolls onto the top of the spigot shoulder and into the gap between spigot and socket during installation. This prevents concrete to concrete contact and gives efficient transverse shear load distribution across the joint.

The rectangular cross section of the laminated sealing body makes the seal very flexible and provides excellent contact width. It is easy and clean to handle as the lubricant is enclosed in the sliding mantle. This allows installation with very little force as there is no friction between the rubber and concrete. Joint performance is dependent on dimensional accuracy and surface finish of socket and spigot.

Trelleborg 140 Lamell meets all relevant current European standards.

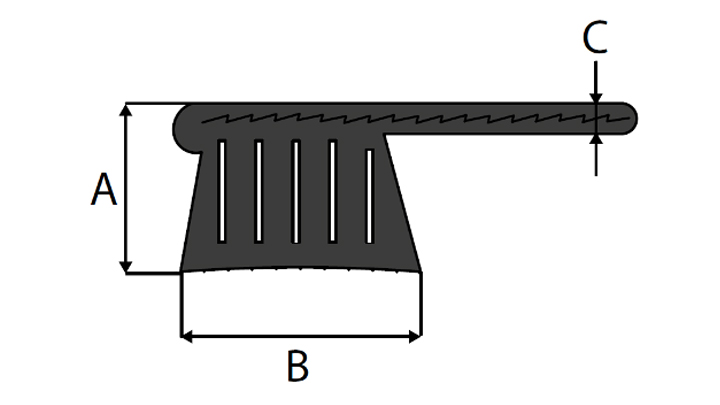

Sizing Chart

| A (mm) | B (mm) | C (mm) |

|---|---|---|

| 13.5 | 17.5 | 2.7 |

| 16.5 | 24.0 | 2.5 |

| 18.5 | 26.0 | 3.3 |

| 20.0 | 28.0 | 2.8 |

| 22.5 | 30.0 | 3.2 |

| 24.5 | 32.0 | 3.5 |

| 28.0 | 35.0 | 5.0 |

| 32.0 | 40.0 | 5.2 |