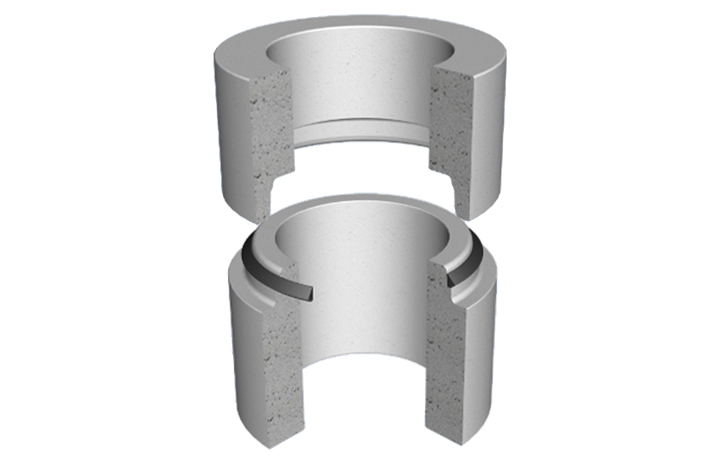

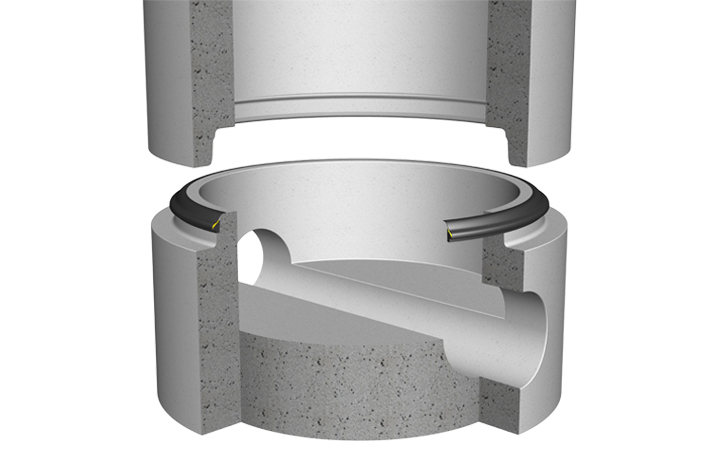

Non-integrated seal for concrete pipes and manholes.

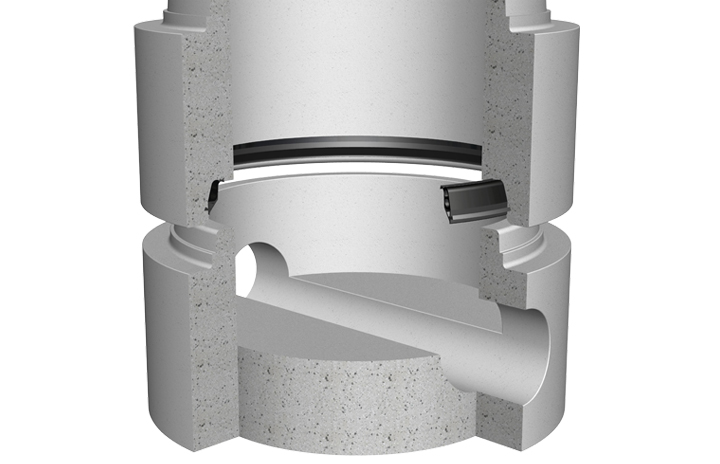

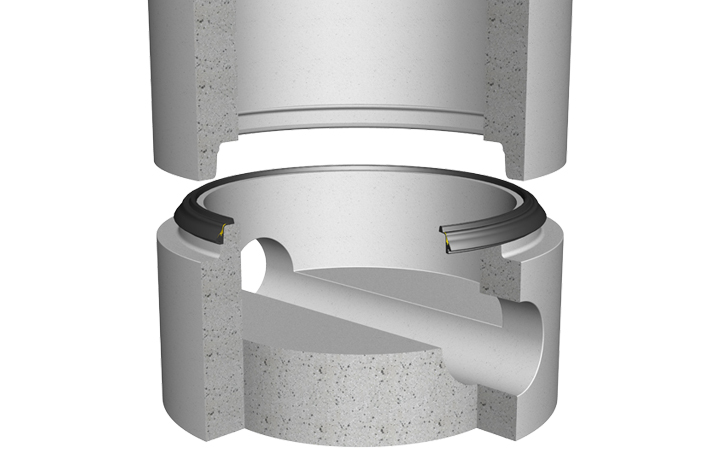

Pre-lubricated seal for concrete manholes.

Pre-lubricated seal for concrete manholes.

Pre-lubricated seal for concrete pipes and manholes.

Pre-lubricated seal for concrete manholes.

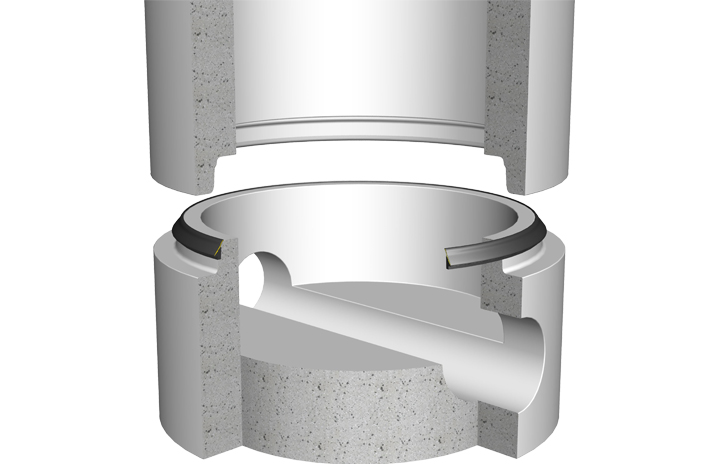

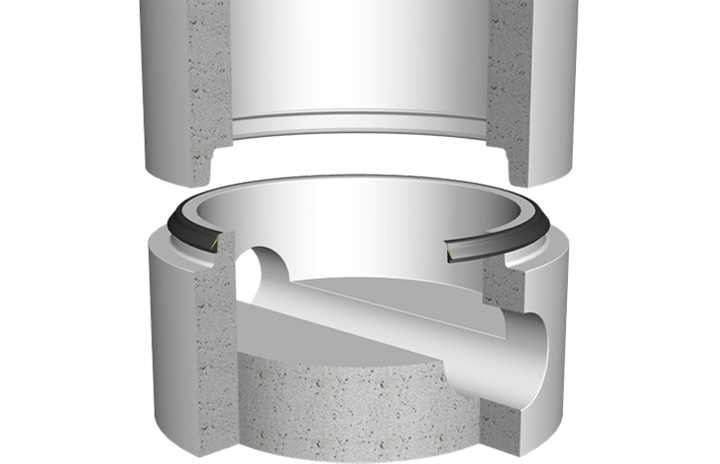

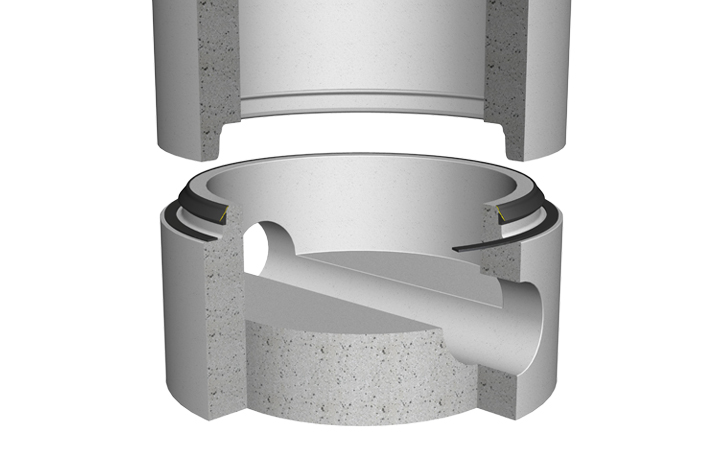

Integrated seal for concrete manhole.

Pre-lubricated seal for concrete manholes.

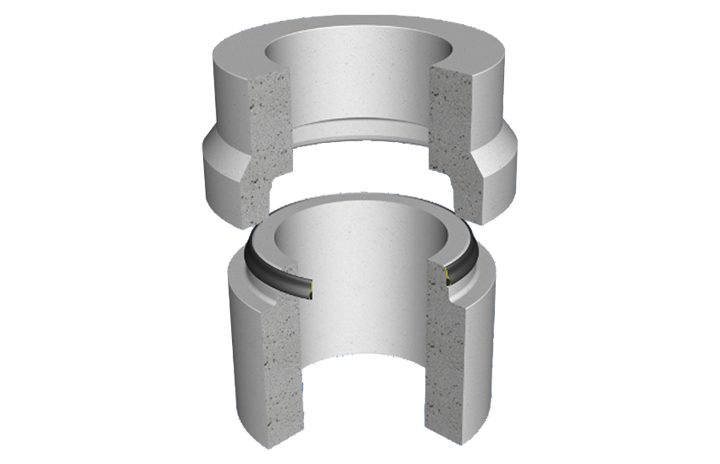

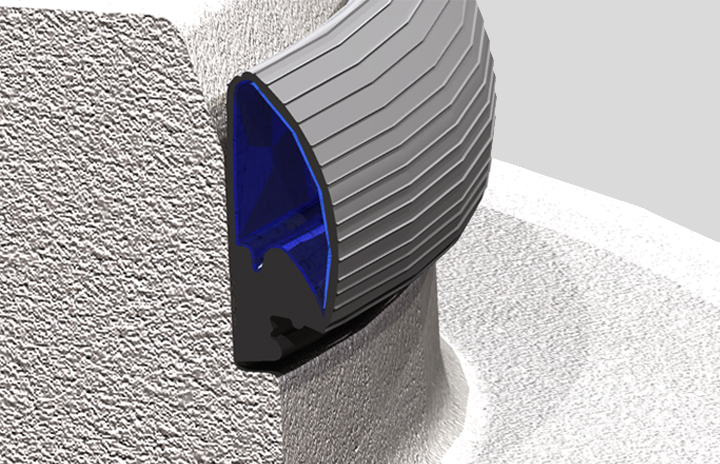

Pre-lubricated seal with load distribution for concrete manholes.

Load distribution element for concrete manholes joints.

All butyl and butyl blend products.