Trelleborg Exhibits Buoyancy Materials at Oceans 2018

Date: 01.10.18

Trelleborg’s applied technologies operation will showcase its range of buoyancy materials at Oceans 2018 in Charleston, South Carolina in from 22 to 25 October. It will give attendees a firsthand look at some of the company’s advanced composite materials, including Eccofloat®, a high-strength syntactic foam, and Eccosphere®, hollow glass microspheres.

Trelleborg manufactures various grades of syntactic foams, called Eccofloat®, to meet deep-sea buoyancy requirements for subsea applications including Eccofloat® TG30, which is the first 6000 meter material at 32 lb/ft3 density.

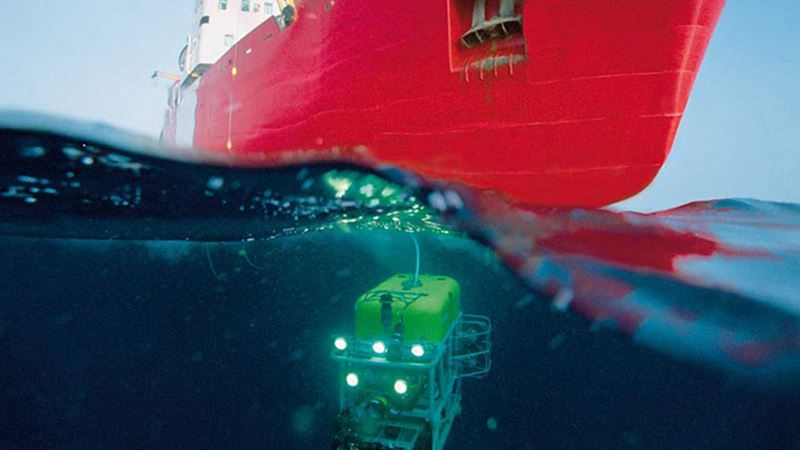

Will Ricci, Business Development Manager within Trelleborg’s applied technologies operation, says: “Buoyancy material is a crucial component of unmanned subsea vehicle design. The composite foam maintains the near neutral buoyancy for free-flood vehicle designs. The neutral buoyancy allows the vehicle to minimize energy consumption while maintaining its position within the water column.

“One of the greatest challenges with manufacturing deep water syntactic foam is making it as light as possible for a given depth. This translates into maximum uplift or buoyancy for subsea vehicles; something our customers are ultimately looking for. Oceanographers, for instance, depend on syntactic foams to suspend instrumentation for deep ocean studies. For these applications, syntactic foam is used in either block form or custom-molded shapes for installation in manned and unmanned submersibles, such as the legendary Alvin and Jason vehicles that were used to discover and explore the Titanic.

“Our complete range of Eccofloat® materials go from 1,000 meters to full ocean depth, allowing customers to select the most appropriate material for their application and depth needs. Recently we have expanded our capability to include highly specified shallow water materials and buoyant thermoplastics for brackets and fairing components”

Eccofloat® syntactic foam provides superior uplift for given depths and has a proven track record to provide maximum years of reliable service. The superior performance is achieved through the use of Trelleborg’s Eccospheres®, hollow glass microspheres that are produced at Trelleborg’s Boston, Massachusetts, facility. The ability to custom-manufacture and test this critical component of syntactic foam allows Trelleborg to provide materials with industry-leading strength to weight ratios.

OCEANS is the bi-annual event for global marine technologists, engineers, students, government officials, lawyers, and advocates. Industry thought leaders gather for four days to highlight relevant topics and current trends, while creating a community of learners and influencers who consistently advance research, practices, and policies for the marine field.

Will Ricci, Business Development Manager within Trelleborg’s applied technologies operation, says: “Buoyancy material is a crucial component of unmanned subsea vehicle design. The composite foam maintains the near neutral buoyancy for free-flood vehicle designs. The neutral buoyancy allows the vehicle to minimize energy consumption while maintaining its position within the water column.

“One of the greatest challenges with manufacturing deep water syntactic foam is making it as light as possible for a given depth. This translates into maximum uplift or buoyancy for subsea vehicles; something our customers are ultimately looking for. Oceanographers, for instance, depend on syntactic foams to suspend instrumentation for deep ocean studies. For these applications, syntactic foam is used in either block form or custom-molded shapes for installation in manned and unmanned submersibles, such as the legendary Alvin and Jason vehicles that were used to discover and explore the Titanic.

“Our complete range of Eccofloat® materials go from 1,000 meters to full ocean depth, allowing customers to select the most appropriate material for their application and depth needs. Recently we have expanded our capability to include highly specified shallow water materials and buoyant thermoplastics for brackets and fairing components”

Eccofloat® syntactic foam provides superior uplift for given depths and has a proven track record to provide maximum years of reliable service. The superior performance is achieved through the use of Trelleborg’s Eccospheres®, hollow glass microspheres that are produced at Trelleborg’s Boston, Massachusetts, facility. The ability to custom-manufacture and test this critical component of syntactic foam allows Trelleborg to provide materials with industry-leading strength to weight ratios.

OCEANS is the bi-annual event for global marine technologists, engineers, students, government officials, lawyers, and advocates. Industry thought leaders gather for four days to highlight relevant topics and current trends, while creating a community of learners and influencers who consistently advance research, practices, and policies for the marine field.

Visitors are encouraged to stop by stand 316 while attending the exhibition to speak with industry experts Bob Kelly and Will Ricci.

For more information, please go to:

www.trelleborg.com/applied-technologies

www.trelleborg.com/applied-technologies

Press Service:

This press release is available for download in English. If you reproduce information from this release please give contact details as:

www.trelleborg.com

E-mail: news@trelleborg.com

English [doc]