Applications

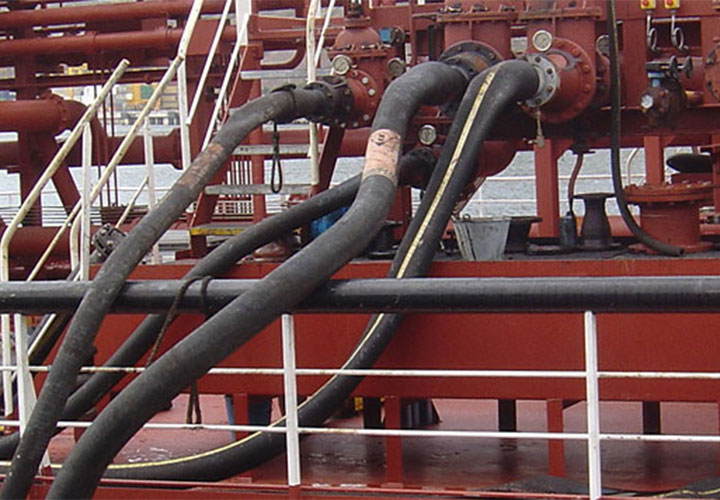

Heavy duty suction and discharge of petroleum products for dock side service, for refined products with aromatic content up to 50%.

Advantages

Smooth inner tube.

Bursting pressure > 60bar.

Low elongation to tensile load.

Design

Technical drawing

Overview

Inner tube

oil resistant NBR, smooth, black,

Reinforcement

synthetic textile cords with embedded steel helix,

Cover

oil and weather resistant CR, fabric impression, black,

Temperature range

-20 to +82

Electrical properties

built-in conductive wire, R<0.5Ω/m (electrical discontinuity available on request).

Standard/Approval

EN 1765:2016 type S15 (supersedes BS 1435-1).

Additional information

Additional weight for flanges, consult us.

HNBR liner available on request for hot oil up to 125°C in continuous service or 135°C in temporary service.

FKM liner available on request for refined products with aromatic content up to 100% or hot oil at 150°C in continuous service or 200°C in temporary service.

HNBR liner available on request for hot oil up to 125°C in continuous service or 135°C in temporary service.

FKM liner available on request for refined products with aromatic content up to 100% or hot oil at 150°C in continuous service or 200°C in temporary service.

Couplings Fittings

Manufactured with built-in flanges: fixed or swivel (ISO PN16, PN20 ASA150, etc.), slip-on, welding-neck RF or FF type.

Other mechanical specifications (diameter, bursting pressure, etc.): on request.

Other mechanical specifications (diameter, bursting pressure, etc.): on request.

Technical Specifications

| ID (mm) | Wall thickness (mm) | OD (mm) | Working Pressure (bar) | Bursting pressure (bar) | Max. vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Article number | Stock or min. order (m) |

¤ Upon availability. * Tolerance on length: ± 1 % (ISO 1307 Standard)

Solutions for Oil & Petroleum Supply Chain

Check out our dedicated video