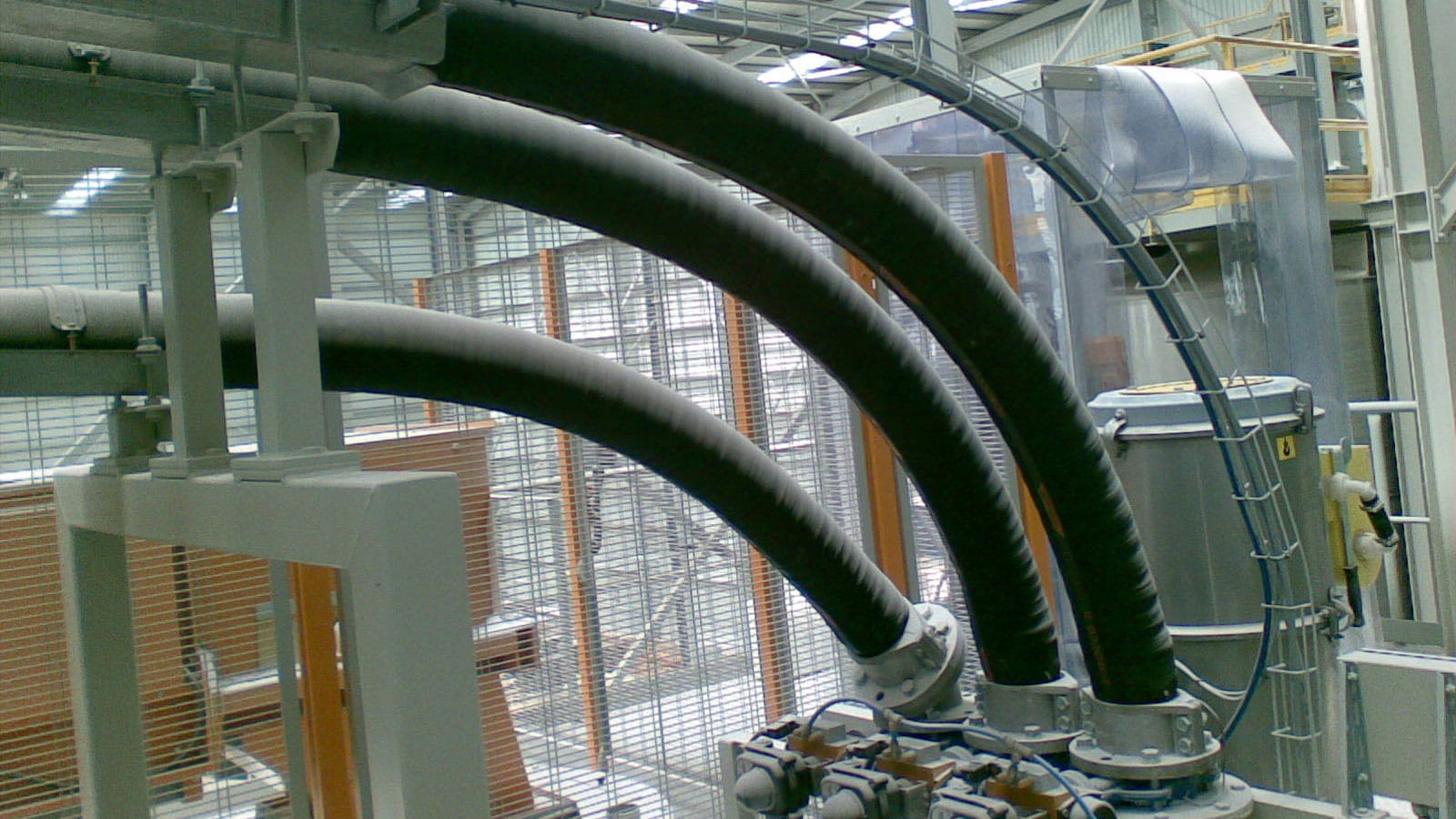

Scirocco II®hose, the flexible airslide

Scirocco II® hose from Trelleborg Industrial Hose provides an alternative to conventional systems for transport of dry powders through a processing system. Using fluidization principles, the unique hose allows easy cost-effective fitment into confined spaces, requires virtually no maintenance and most importantly uses less power. These factors mean that Scirocco II® hose can contribute to significant savings in overall processing costs.

Application

Scirocco II® hose is an alternative to conventional methods of transporting powder through processing systems such as screw, belt or air slide conveyor systems. The hose operates on the fluidization principle in which a granular material is converted from a static solid-like state to a dynamic fluid-like state when a gas is passed up through the granular material. Uniquely, the fluidization system of Scirocco II® is vulcanized into the lower wall of the rubber hose. This incorporates air supply ducts from which small openings lead into chambers covered with a breathing cloth membrane.

Customer references

For 15 years, numerous customers have been using our Scirocco II® with success.

Cementa Heidelberg Group, Sweden.

Download the Press Release.

Lafarge, France.

Download the Press Release.

Sakret, Germany.

Download the Press Release

Cementos Puma Spain

Download the Press Release

Martinswerk, Germany.