Trelleborg's Vision

Business concept

Trelleborg uses natural rubber in springs and rubber bearings as well as its hoses, seals and coated fabrics. Synthetic rubber, such as styrene butadiene rubber (SBR) and isoprene rubber, has properties that are similar to those of natural rubber. In mixes, it is used as outer rubber in blasting hoses, oil and gasoline hoses and more. Nitrile rubber (NBR) is often used with other types of rubber for added elasticity, abrasion resistance and ability to withstand low temperatures. Ethylene-propylene rubber (EPM/EPDM) is suitable for high temperatures and used for sealing profiles, hoses and more.

How we are organized

Core capabilities

We Know How Your Industry Works

We Work To Build Your Business

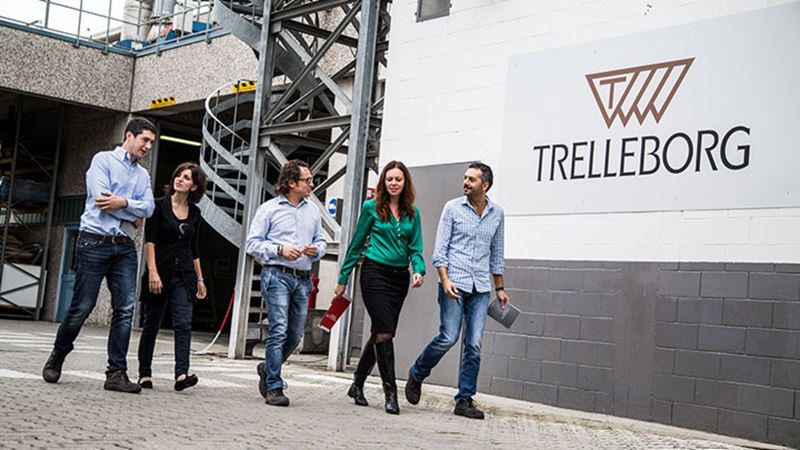

Part Of Your Team

The Experts In Polymer Engineering

Local Presence with Global Reach

Core values

Trelleborg Strategy

Trelleborg’s strategy aims to build or maintain leading positions in selected industries. With the more coherent portfolio resulting from the divestment of the tire operation, combined with an accelerated focus on growth industries, the Group will have a better growth profile and higher profitability, while operations become less cyclical with an improved sustainability profile.

Among Trelleborg's important global competitors are Contitech, Freudenberg, Hamilton, Hutchinson, Parker Hannifin, Roxtec, Saint Gobain and SKF.